Is your bike safe to ride?

One Slowtwitcher stated, during a forum discussion, "If you could point me to publicly available, detailed information on the QC process by any of those, I'd be impressed."

He's got a point. Not enough bike companies talk about their testing, and not enough magazines write about it.

My thought was to write companion articles that talk a bit about what goes on inside the frame (stuff you can't see) and behind the scenes. One is written, and you'll find a link to it (Beauty on the Inside) appending to this article, just below it.

This is the other, and it flowed from visits to the bowels of Felt's headquarters, as I have done on numerous occasions, to talk to its director of engineering Jeff Soucek. I like asking him about their product testing, and not just wind tunnel or Alphamantis testing but the kind that keeps my bike and its parts from failing (a slow bike ride means a kinda bad day, a failed bike underneath me means a really bad day).

But this isn't QC, and sometime I'd like to write about that in depth. Felt employs a number of full-time employees in Asia who travel from factory to factory, and every reputable brand has these. Most companies like Felt have their carbon bikes manufactured and assembled in the Orient.

There are typically three kinds of factories over there used by these companies. One specializes in making the bike frames themselves, and it works very closely with its American customers on the frame molds and lay-up schedules (see Beauty on the Inside). A second factory is simply for complete bike assembly. Finally, there are factories all over Asia that make sub-assemblies: that forge, extrude, machine, mold; who draw and bend tubes; and who make all sort of parts from saddles to aerobar armrests.

A quality control agent won't stand over every part made by every employee, but will spend a significant number of time at each factory making sure that the go, no-go standards the company sets up in advance are adhered to by the factory. It's not in the interest of the factory to skirt these guidelines, because if a product is rejected that QC agent will start looking at every part. The factory won't get paid on rejects. It's important to have the QC agents there, not stateside.

Felt tests some of its frame and fork products at its headquarters in Irvine, California. It will test both its own and its competitors' products, and some companies (Cannondale notably) are famous for its lab that also tests the components that go on its bikes (for things like cable fatigue failure, saline corrosion, and so forth).

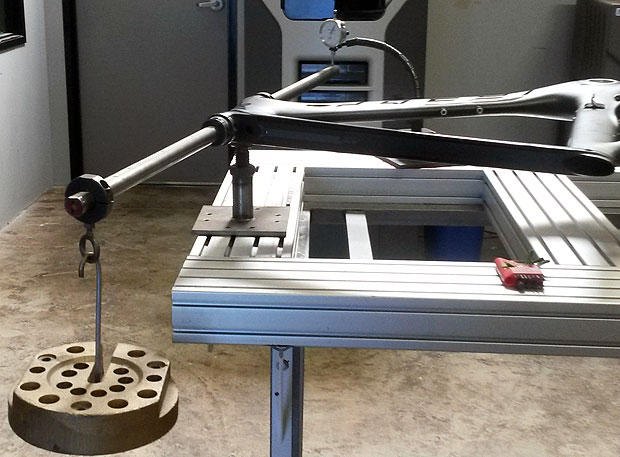

The image above tests frame deflection when weights are applied to certain areas and the frame is fixtured in different ways. A frame maker might want to know how much a frame deflects, and maybe where it deflects, i.e., where the bending occurs in the down tube. What would you do as a response? Wrap the downtube with carbon, test it again. Once you like the way your frame adapts to the change you made in the lab you'd translate this into a change in the lay-up schedule. Then the frame is manufactured with the change in the schedule, it comes stateside, you test it again. Then, of course, you ride it. And you test the entire bike for both fatigue and ballistic stresses.

When I was a bike maker we tested our frames much the same way as the image above, but not quite. We had a piece of 4-inch square stock coming up from the slab, with a fixture atop it that accepted a frame's bottom bracket shell. Our frame was perched upright for this test. We affixed a stem and a straight tube through the stem, and the fork dropouts were allowed to flow back and forth as a torsional force was applied. That force was in the form of a weight hung from one end of the "handlebar," and measured the deflection of the head tube relative to a vertical line. This is how we came upon the shape and the lay-up of the carbon gussets we stuck into our otherwise aluminum Kilo Private Reserve frames (a bike that might be remember by those who've been in the sport for 20-plus years).

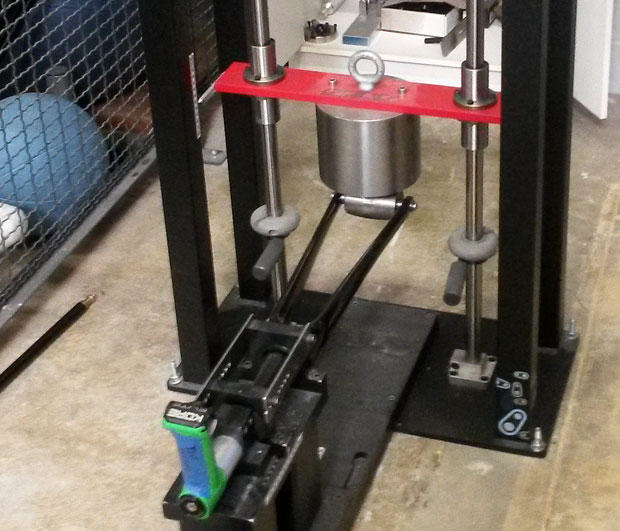

The image above is of a 10 kilogram weight dropped on a fork, testing the ability of that fork to withstand a frontal impact (like a curb or a pothole). The operative metrics are the height above the fork from which the weight is dropped as well as the number of times the weight is dropped onto the fork before the amount of deflection demonstrates that the fork is failing.

This is one of a number of tests a fork will undergo, including fatigue testing, which might be a fraction of the energy applied to the fork in this ballistic test, but such force applied over a period of time, maybe 100,000 cycles. You might start such a fatigue test on Friday, show up Monday morning and see how many cycles your fork withstood before deflection that signifies failure.

In my factory we built a structure we called The Guillotine, much like this test machine above, except we tested front-end failure of our frames. We put a fork-like structure into the frame, but it had one "fork blade" protruding from the crown and a metal strike plate on it. We dropped the weight from a specified height, and noted how many times it took before the frame began to buckle. We were interested not only in how the frame withstood the failure, but how the frame failed (not all at once, and not in pieces).

How did we know what was acceptable, 25 or so years ago? We didn't, in terms of an agreed-upon protocol. We were cheap (because we were broke). We had written in our athlete contracts that the athlete "traded" our bikes for the most recent bicycle the athlete raced on prior to entering into a contract with us. We tested all these bikes to failure. We didn't know how durable our frames should be, but we reckoned that if they were as or more durable than the best of our competitors' bikes, it would place us on sound footing. Again, the carbon gussets we placed in our frames added notable frame strength, as this test proved to us. This is why, even up to today, I love to see frames that are deep from the leading to edge of the head tube to the trailing edge of that head/top/down tube complex.

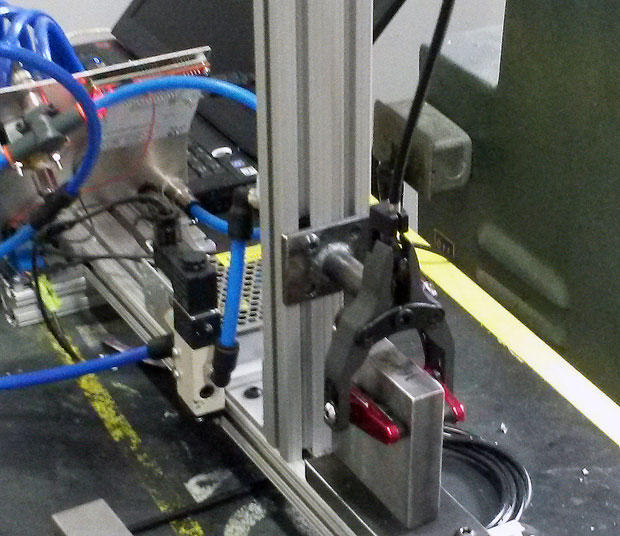

Speaking of fatigue testers, here's one of these pictured above, again from Felt's lab. This is for brakes, notably center pull, which is important to Felt because more and more, one assumes, of its bikes going forward will feature these. It's not only tri bikes but perhaps aero road bikes that might feature center pull brakes. These brakes are often made by brands that might not have the same attention to testing sensibilities that attach to Shimano, Campagnolo and SRAM. At Quintana Roo we made our own center pull brakes for our tri bikes in-house via our own CNC mill, so it might be that companies like Felt and Specialized may choose to do the same. In this case you have to do your own testing.

In the case above a strain gauge is built into a metal disc that approximates the width of a rim braking surface. The brake is applied using the force typical of a person during braking. Nothing magic here, just a person squeezing a brake lever with an amount of force that is intuitive and comfortable. Read the strain gauge, see what it says. The machine above is pneumatic, so, you adjust the air pressure to the desired force. Test until failure.

Some of these testing machines have prescribed protocols. The CPSC or similar body – depending on country or continent – might have a prescribed test, as they do for helmets. In other cases, no, so you design the test to exceed what you expect to be the lifetime use of the product.

When I was a small bike maker producing tri bikes back in the late 80s and 90s, I don't think the testing in our industry was nearly at the level it is today. I would be shocked if any of the small frame makers who built frames and forks back when I started cycling built frames simply to destroy them in a testing machine. But it's a common, if not morally mandatory, practice today. It's one of the steps that makes a brand a brand, and all the testing – performance and safety – and the engineering, and the QC, is what conspires to add price as well as performance to a brand's bike.

I would estimate software licenses for CFD, CAD and FEA to be way into the six figures for any reputable brand, and these are recurring charges. Engineering, software, QC and testing budgets for today's brands dip into seven figures per year, and that is the case even for a brand selling only $20 or $30 million worth of bikes. These costs rival or maybe exceed marketing costs.

It makes me glad I'm not making bikes today.

Start the discussion at slowtwitch.northend.network