When Craft Gave Way to Engineering

I broke into the bike business in 1988. And, when I say I broke in, I was a burglar, or maybe a hijacker. Credentials? I had none. But I had some practice at burgling. I got into the wetsuit business the year before with bolt cutters and a ski mask.

Not that I didn’t know my way around bikes, just that I knew then what you know now: whatever a user knows. I started racing bicycles in the late 1970s, and was a triathlete from 1980. I had that knowledge, a customer list, and a warehouse.

Today? Yes, I know a bit more than I did then, but I still don’t have Gladwell’s 10,000 hours. What’s notable about my manufacturing era, for the purpose at hand, is that particular moment in the history of bike making. The late ‘80s was an inflection point, where the making of pro bikes ceased to be a hobby, a craft, an art, and became an industrial enterprise.

My user history began with the purchase of a secondhand Raleigh International, from which I graduated to a secondhand Colnago frameset (swapping the parts over). I raced the Hawaiian Ironman in 1981 on that Colnago.

I bought my first new bike in my 8th year of cycling. It was a Della Santa custom made for me in 1984. Mind, we’re talking steel tubed bikes up through this point. Prior to the mid 80s most of us obtained our pro race bikes via one of four channels: Large Euro maker (Raleigh or Peugeot); Schwinn's Paramount factory; mid-sized Italian (Colnago, Bianchi, De Rosal) or French (Legnano, Frejus), or English (Ron Cooper, Holdsworth); or a small, US-based custom bike maker (Serotta, Eisentraut, Della Santa, Sachs). They were in almost all cases steel-frame bikes.

Cycling was heavily Euro-centric. But things were changing. Trek had begun making pretty good steel bikes by the early 80s. We all observed a pair of companies, Alan and then Vitus (from Italy and France respectively), bonding aluminum and carbon tubes into bike frames in the late 70s and early 80s. Trek began to emulate them. So did Specialized. So did Giant. By the mid-80s bonded round-tubed carbon bikes began to supplant steel as a race motif, and Craig Calfee perfected that tech. Triathlon was an early adopter of all the above.

But the real game changer was Kestrel, founded by some of Trek’s original team. Not only was the 4000 (above, circa 1987) the first monocoque carbon frame, this company was driven by engineers. As a brand owner I was already behind the tech curve before I began. I used master frame builders – who made their frames out of steel – as contractors. This historical moment – the decade between, say, 1985 and 1995 – was the time of greatest change in how bike frames were made, and in how the industry approaches bike making.

Two companies stand out as engineering-driven during this decade, and both have a heavy intersection with triathlon: Kestrel and Cervelo. Yes, I had a company in there too, and I battled with both these brands. But my brand wasn’t built on materials tech, rather on fit, handling, ergonomics. Still, I just didn’t feel that I could continue forward continuing in the craftsman heritage. We began to set aside a number of our products for testing to failure.

Testing

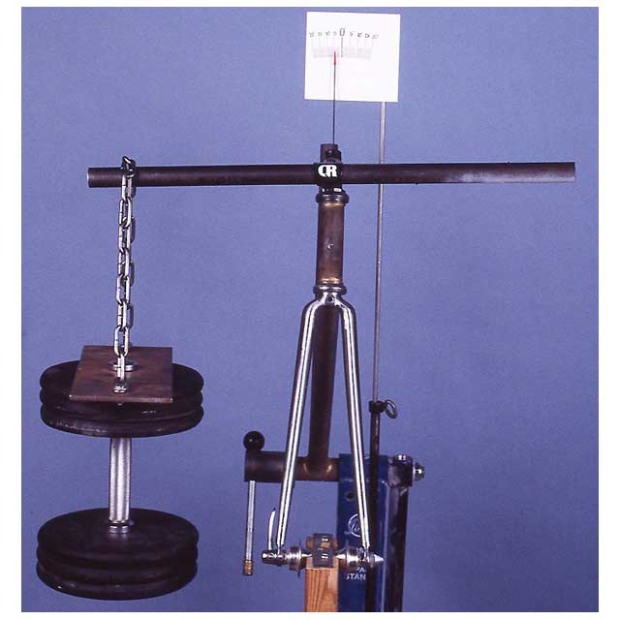

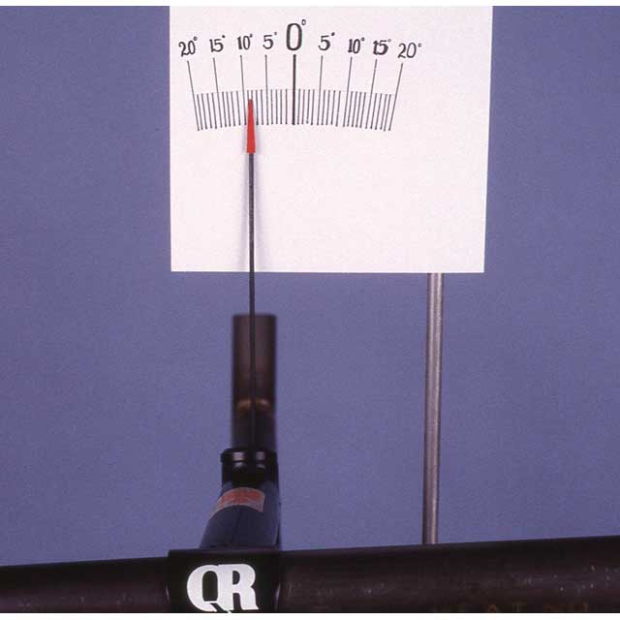

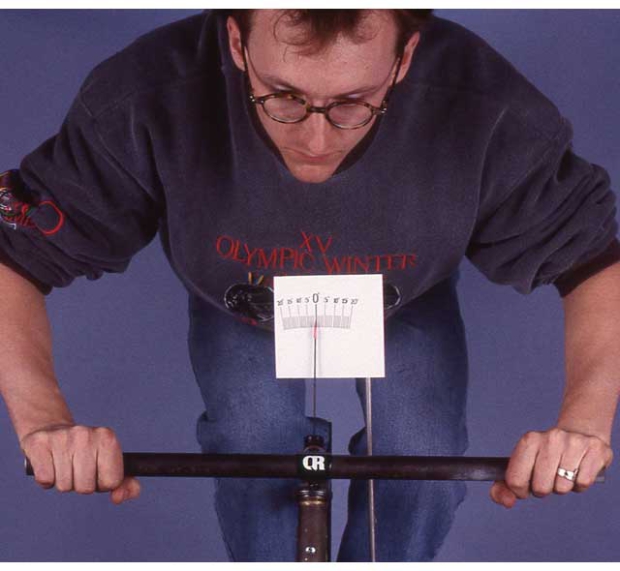

My own testing back then (these photos are from circa 1991) mirrors in theme, if not polish, some of what's getting done today. For example, just above is a frame from right around 1990, maybe 1991, during a time when we were migrating to new materials and the integration of different kinds of materials. You may’ve heard, “Buy the smallest frame that fits.” In my opinion, this flows forward from the time I started racing, when bikes were made of steel, and there was no good way to make a frame larger, and larger, using basically the same materials, and for that frame to remain stiff. Imagine two of us each holding one end of a ladder, and twisting it.

I didn’t want my tri bikes to be bound by this paradigm, so I asked my friend Steve Hed if he could make me gussets I could epoxy into those steel frames made in larger sizes. This test above allowed us to quantify how our frames responded to the addition of these gussets.

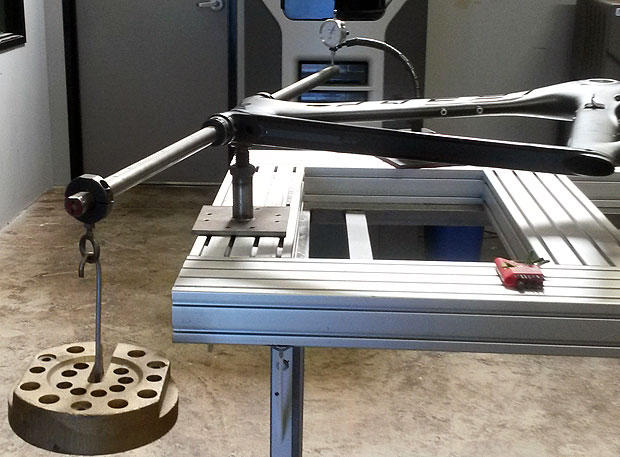

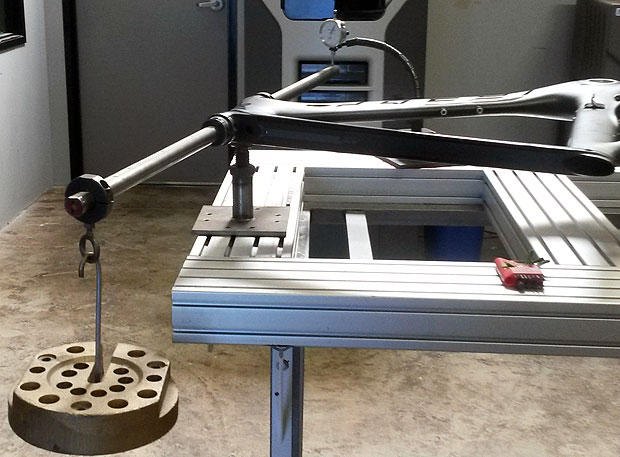

Just above is how Felt tested the response to different carbon layups in its frames, when I visited their testing lab a couple of years ago. You’ll note that Felt’s lab is a bit more high tech, but we were each after the same output.

I regret that I don’t have a picture of our Guillotine. Imagine the frame in the picture highest above, just, imagine it pointing straight up, as if it’s climbing vertically into the sky. We replaced the fork in our frames with one that had a single leg and a square strike plate at the end, where the dropouts would be. Down came a 50lb weight, dropped from 5 feet up, over and over.

I didn’t feel our engineering capacity could generate results beyond which we could achieve through testing. And, we weren’t wealthy. We placed in the contracts of our athletes a clause: they must send us their most recent racing bicycle in exchange for the first bicycle of ours that we sent them. In went the fork with the strike plate, onto the Guillotine went the bikes we got from our athletes.

We destroyed a lot of bikes, such as this one above. The imperative for our own bikes was that they outlast the competition. One bike we could never beat in testing, however, was that Kestrel 4000. It was a tank. It is ironic that this company’s undoing were surface cracks in the paint. Kestrel just could not – it seemed to me, as an outsider looking in – find a paint that was sufficiently elastic. The company eventually sold to Schwinn which, itself, succumbed to bankruptcy. (Kestrel is alive and prosperous under the ownership of Advanced Sports Industries.) Just, if Kestrel’s (then) customers knew that beneath these surface cracks was a bike that was beyond bulletproof, and if they could've look past the minor cosmetic imperfection, one wonders if that might’ve changed the trajectory of that company.

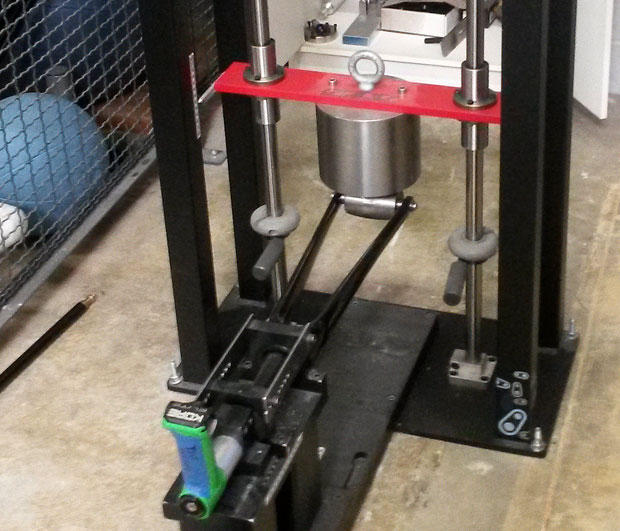

Below is another machine from Felt, and when I first saw it I had to smile. Felt has its own Guillotine, in this particular instance testing a fork to failure.

I left the industry in 1999, and not a moment too soon. My time had passed, as a manufacturer. I spoke to Damon Rinard about this, because he was around to see it all, and with a pretty good vantage point.

Engineering is Discovered

"There were only a few companies doing testing or engineering in those days,” remembered Damon, reminiscing about that decade from 85 to 95. "Schwinn did a lot of testing. Before they bought Kestrel – shortly before I started working there, around 1998 – they tested a Kestrel 4000 and set new records for strength and long fatigue life."

Preston Sandusky was the chief engineer at Kestrel at the time, and inspired Damon to go back to school to get his engineering degree. It was clear to Damon that the writing was on the wall: engineering and testing is where the industry was going. Today Damon is Cannondale’s Engineering Manager for Road Bikes, and I hope you can see a progression from the Kestrel 4000 to the Cervelo S5 (Damon engineered at Kestrel, then Trek, then Cervelo, and now Cannondale), through to the just-launched Cannondale SystemSix.

The steel tube makers were feeling pressure to move out of the craftsman approach. "Reynolds did some engineering,” Damon remembers, "like certifying frame builders before allowing them to buy 753.” And he notes that, "Columbus did some engineering, collecting strain data as a bike was ridden.”

But this was the exception. “Framebuilders in the steel days, didn’t really. Like you, I built a frame, mine in 1983 and the only ‘engineering' I did was order a Columbus SL tube set and some Cinelli investment cast lugs.”

Was Craftsmanship Lost?

What became apparent, to me, starting around 2005, is that the move to engineered bikes, which essential, while undeniably positive, elbowed out a good deal of craftsmanship. The artisan was a casualty. It wasn’t simply art that was lost, but definable elements of the user experience.

One very obvious example was in the variety of geometries available. By 1995 it was pretty easy to buy a carbon monocoque bike, just, you'd better like its geometry. It wasn’t until the price of a new model – the engineering, the cost of the molds – came down that we started to see the second and third geometric expressions (as in Trek’s H1, H2 and H3 geometries).

The second engineering “mistake” was in assuming that stiffness was always a virtue. It took a long time for Germany’s Tour Magazine to figure out that extra stiffness wasn’t better, just extra.

Bikes are a little bit like wine. Making wine is no longer just a hobby or a craft, but a big industry, and is very tech driven. Still, is the wine itself better than it was, say, 50 or 100 years ago? It's certainly more uniform; more predictable. But is the best wine better now than then? I asked Damon if he’d be willing to talk to me about what craftsmanship we’ve lost over the past 35 or 40 years, and how to get it back – how we might marry it to the tech and testing we have today. If Damon and I have that conversation I’ll report on it here.

Start the discussion at slowtwitch.northend.network