Scott Plasma Premium: From Thought to Reality

I built up a couple of bikes from the bare frame last week, the bike profiled here and a Diamondback Andean I'll be writing about soon.

This black bike with yellow-green trim, it’s a Scott Plasma Premium. It's won a lot of races: national TT championships, the Hawaiian Ironman WC, the 70.3 WC among them. Below I’m going to explain how this bike got chosen for the purpose at hand, and then I'll talk about the process of building it. I’m going to get way personal into the riding life of its new owner, Sika Henry, who has been the subject of a couple of Slowtwitch articles and will be the subject of a couple more (including a 2D Motion Capture discussion upcoming).

The process began with my meeting Sika at the Triathlon Business Intl conference last year, where she spoke on diversity in triathlon. Very long story short, as good as she is in running (3-flat open marathon) is as bad as she is in cycling. Upon reflection and looking at some images of her on the bike I felt that position was nine-tenths of her problem.

Slowtwitchers know what I recommend in cases like this! Below is a screenshot of her position after I did my thing.

What is the most important set of metrics here? Depends what you’re interested in knowing. Is the position proper? Will she generate power? Be comfortable? That’s where motion capture can help. Are the angles her body is generating inside the ranges we expect?

Once all that is decided, and we want to know what bike matches the position, then the important metrics are Pad Y and X, that is, the rise and run from the bottom bracket to the pads (pad center in the case of Scott).

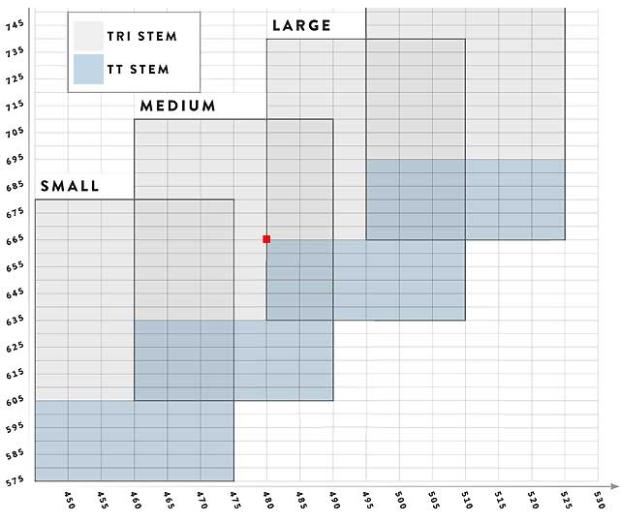

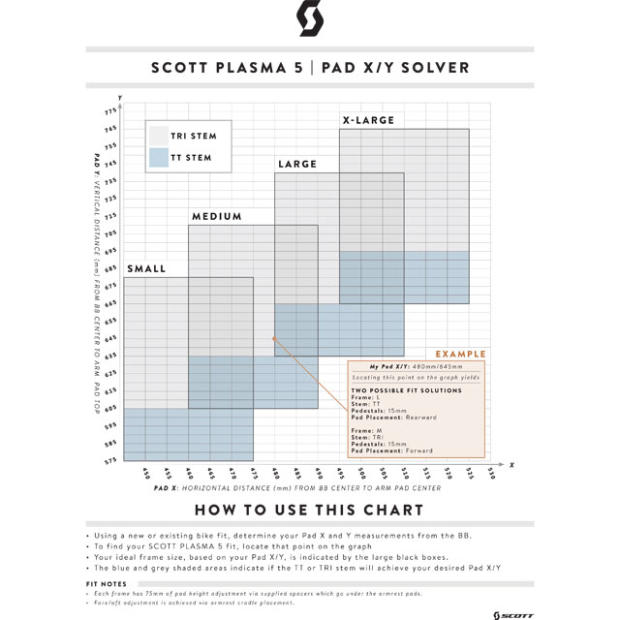

We could have seen whether Sika wanted to ride a Cervelo, a Canyon, a Diamondback or a Felt. Would she fit on a Quintana Roo or an Argon 18? It’s easy to prescribe exactly what she needs if we have the Pad Y and X of her position. Sika was previously riding a Scott and liked the idea of riding another. So, we looked at the prescriber for the Plasma Premium, and just below is a detail shot of that prescriber (at the bottom of this article is a link to the prescriber and how it works).

Her Pad Y of 665mm and Pad X of 480mm (where the red dot is in the graph below) gave her two size solutions, but she was at the edge of the size L and right in the middle of a size M, so we chose the M. I built the bike from the bare frame and it was pretty clear what I needed to do to get it to fit correctly: The pads were very close to the center of the fore/aft range, and we needed 30mm of pedestals under the armrests to match her Pad Y of 665mm. (If you ponder that chart below I think you can see how the chart revealed this as the fit solution.)

We had to settle on parts. Sika had a bad experience derailing from big ring to small, and found that too often she just neglected to shift into the small ring (even when that's what she needed to do). Also, she had a budget. All that screamed 1x! So that’s what we put on her new Plasma Premium frame. (And I wish that frame was more often purchased as a bare frame, because it wasn’t a bad home-build experience as you'll read below.)

I got shipped to me a Force 1 groupkit, which consisted of shifters (1 of which I used), crankset in 170mm, GXP bottom bracket, chain, 11-36 cassette, and a 52t X-Sync narrow/wide chain ring. It all went together well, and the only question I have is the chain. I put every bit of the chain on. The RD cage would have accommodated a couple more links. Would that be better? I don't know.

I routed the brake and RD cables first, before putting in the BB, because from prior experience one knows that one needs that open bottom bracket for cable routing. The (integrated) front brake was a little bit tricky, but not bad really; the back brake was pretty straightforward. The brakes, fork, headset, all that comes pre-assembled, so, the thing seems half built out of the box.

The only snafu was that the rear brake routing (housing the whole way) had enough length to it, and enough bends, that I felt more comfortable using a thinner shift cable than a brake cable. (I used a 4mm shift cable inside of a standard, spiral wound shift housing). Not ideal. But I checked and the cable head seemed a pretty good fit inside of the lever cable stop, so that’s what I went with, if only temporarily.

The RD was tricky because I didn’t understand the cable routing. The Plasma's tech manual, online, wasn’t 100 percent clear at the time (it seems pretty clear in retrospect). The upshot: It’s cable housing the whole way, from the brake lever to the derailleur. What confused me was a goober in the chain stay, about 3 inches from the dropout. I didn’t know if the goober was a goober or something there for a reason. In the end I just pushed a screwdriver in there and hogged the goober out.

In the pic below you'll see the housing exiting the frame, and you'll also see a B-screw which I'll talk about in a minute.

I measured that RD cable run at 1900mm, and that’s not including however much excess sticks out past the fixing screw at the RD. Most shift cables are 2100mm long. I recommend having on hand, as a tool, not just as a component, 2700mm or 3100mm cables. For tri bike use I just think it's safe to buy your shift cables a little bit longer. I say I use these as tools because you can’t route these internal housing runs unless you first fish a cable through the run, then push the housing over the cable, using the cable as a guide. You’re going to go through some cables in just that way.

Below are the tools you need to install the BB and the crank (besides an 8mm Allen Wrench, and a torque wrench if you want to do this by the book). You don’t need all these tools, but you do if you’re me. One thing you’re looking at here is a headset press. You need this to press in each side of the BB. (Why a headset press instead of a BB press? Long story.) Pressing in each side of the BB goes smooth. No big issue here. Except if you discover that the crank spindle only passes through one side of the BB and not the other.

Once you discover this, and assuming you pressed the left cup into the right side and vice versa (which I did, because I failed to read the instructions first), then you need that thing that looks like the (exploded) barrel of a gun after Elmer Fudd shot it with the potato stuck in the end that Bugs Bunny put there. You push that doo-hickey through one side of the BB; once the splayed “fingers” pass through and go sploing like a tuning fork then you bang on the other end with a rubber mallet and push out the BB cup you were fool enough to insert on the wrong side. Then you bang out the other side. Then you press in each BB half correctly. (In case it isn't clear, you press in both sides of the BB at the same time with your headset press.)

Two things about this bike were curious to me. First, I had never built up a 1x before that I can recall and those who work on bikes will know that there are 3 adjustment screws on derailleurs (besides the barrel adjuster): the hi and lo limit screws, and the “B screw” or “B-Adjust screw". That B screw adjusts the distance between the upper pulley and the cogset. What SRAM recommends is 15mm between a cog tooth and the a tooth on the upper pulley.

I found that the B screw adjustment, while important in any case, is even more important on 1x. Sika’s bike just didn’t shift well if that B screw was even just a bit out of adjustment. Specifically, I had a hard time getting the chain onto the largest cog unless the B screw was precisely adjusted. SRAM gives you a physical guide for adjusting the B screw, or just measure it to 15mm.

The second novelty about this bike was the front hydration system (above and below). I knew Scott really moved the ball forward with this system but I had no personal experience with it. It’s a marvel. If someone told me that Scott spent as much time and money designing and tooling the front hydration system as the entire rest of this bike it wouldn’t shock me.

When you get this frame it comes with parts and you’d better not throw anything away because it might be part of the hydration system. There are three rubber-foam boots that fit with keyways into the frame or the hydration system, and these boots both aid in the stability (and vibration absorption) of the system as well as fair the whole complex. After I built this bike I took it for a ride, and then Sika and I went on 3 rides in 3 days and we never any issue with the hydration system or its component parts. It’s rock solid.

Sika is extremely leggy: 795mm saddle height, very tall for someone 5’10” tall. This creates a lot of fit problems but, in general, these problems go away if the rider is willing to ride quite steep. There are two places any bike has to fit: The bike must allow the pads to be placed where the rider needs them; secondly the frame must allow the saddle to sit in the position the rider needs. We knew from the fit exercise above we would have no trouble with pad placement. But the saddle? Could we get it forward enough? The Ritchey seat post hardware on this bike works great. You'll see it used on a lot of bikes, including the DB Andean I just built. As you see below, the saddle position is quite forward, but the Ritchey system has so much adjustability it is no problem. (Incidentally, TriRig's "Beta" rear water bottle carrier is designed to be used with this Ritchey system.)

Sika rides an ISM PR2.0, which I find is the single most frequently wanted ISM when I fit people and it wouldn’t surprise me to find out it’s the best selling tri saddle SKU.

The front derailleur boss stays on in case Sika repents of her 1x set up, but so far she’s very happy with it (no FD derailing!).

Those who have the eagle eye will note that these aren’t the aerobar extensions that came with the bike. I had a set of Profile Design T3 carbon extensions that I used as replacements for the standard bend aluminum extensions because I like the T3 shape ergonomically and this extension works nicely for mechanical in general and 1x in particular.

I had a set of HED wheels I hasn’t using for the moment so these are went onto this bike, along with a set of Conti 4kSii. For a spare I put a Topeak valve extender onto a standard 52mm presta valve (which I left open), and this will suffice as the spare tube for either the 90mm front wheel or, with the valve extender unscrewed, the disc.

The new owner has had her bike up to 45mph on descents, and she’s climbed 11 percent grades. No rubbing, no speed wobble, no gears she's missing, no rattles: a superbike that actually functions like any bike should. Beyond this, follow Sika Henry's own writing for her further Scott Plasma Premium and SRAM Force 1 adventures.

Start the discussion at slowtwitch.northend.network