The Lowdown on Zipp’s New 303s

Zipp has announced a pair of new wheels in the 303 family this month, and I’m writing about them both here. One is the 303 S, and this is a more midrange, value-priced carbon wheel at about $1,300 per pair. While this wheelset is half of what you might pay for a premium HED, ENVE, DT Swiss or Zipp wheel, you might think that $1,300 is above midrange. But I stress that it’s carbon, and that it’s actually a *wheel brand*. I draw the line at times, in my own riding, and a brandless hoop out of a factory not managed by people who ride bikes for a living I will not ride.

It’s not that I’m a snob. My ride preferences are changing. Take last weekend for example. I rode a couple of days in the Southern Sierras, north of Kernville, California, and if I’d have DNFd either of these rides it would have been a real problem extracting myself. I’m a snob about not getting stuck somewhere.

Also, I’m moving to tubeless, and I’m picky about my tires, and I think I know where technology is trending in broad strokes. In the future rims will be built for tubeless; with wider inside bead widths; straightwall (hookless) rims; disc brake thru axles; with body drivers that accept 10-tooth 1st position cogs; 12sp cassettes; and built into multi-use-case wheels. This is what the 303 S is (if you buy it that way; you can also buy it with a standard Shimano-style cassette).

One of the great failure stories in cycling is the story of the 303. Zipp brought this product to Europe, maybe a decade or more ago, with the idea of this being a Classics wheel, and the wheel didn’t last one cobble sector in training when used by SRAM’s pro riders. Zipp slunk back and got to work, and very long-story-short the 303 eventually became a road wheel perfectly good for gravel. Out of failure came success, and these wheels Zipp are just now launching are multi-use-case: road, CX, gravel.

This follows my sense of the market, where all wheels are getting built for tubeless, many 23mm to 25mm between the beads (inner diameter), which means all wheels can take tires from 25mm to 50+mm, which means wheels like these can be used just about anywhere, for anything, on any road surface. Many or most of these wheels are now built so robustly that they can be ridden on any terrain. Wheels I’d ride in a triathlon are not that far off from being good candidates for gravel. And, because of these wider inner bead diameters tire pressures get reduced, which speeds up the transition to hookless rim construction.

I’m going to build up a road bike this month, and I’ve asked our Reader Forum folks for their input. My existing road bike has been my everyday road rider for about 8 years, so I reckon I’m due. While the 303 S, and the 303 Firecrest (more on that in a minute) can be ideal for gravel, I’m considering just making the 303 S my road wheel on this new bike, because (whether it's Zipp, CADEX, or any of the other brands I'm riding) there is little-to-no difference between gravel and road wheels among the premium wheel brands.

Except when it comes to wheelsize! And this is the one critique I have of the new 303 wheels. Once you get up above 23mm or 24mm in inner bead width, the sky’s the limit on tire size. On that aforementioned Sierra gravel trip I had some ENVE G27 wheels on my OPEN WI.DE, with 53mm tires, but that tire only really works on today’s gravel bikes (any that I would ride) if mounted on a 650b (27.5”, 584mm bead diameter) wheel. (Tire clearance, shoe overlap, and overall geometry assumes a particular wheel radius.) Neither the 303 S nor the new 303 Firecrest wheels are made in that wheelsize and I think that’s a loss. Maybe in the future.

The 303 Firecrest is not as midrangey, pricewise, but it’s not outlandishly priced. You’re looking at $1,900 for a wheelset. Don’t gripe to me! Remember, I wrote about HED’s Eroica gravel wheelset, starting at about $800 a pair, and I just took delivery of several sets of those for loaner bikes I have here at The Compound. You can get wheels for $400 a pair, or $600 a pair. Or these HED Eroicas. But the Eroica Carbon is priced just about where these 303 Firecrests are priced. We write about them all.

It’s funny. I used to think that the things that matter in wheelsets were spoke count, spoke lacing, bladed spokes, and I just don’t think much about that stuff anymore. Yes, these wheels are light, with the 303 S at about 1500 g per pair, and the Firecrest at 1350 g a pair. But… now I think about the quality of the hub, the ability to put the cassette I want on the hub, is the wheel straight, will it remain true, is it going to break when I roll over a dry riverbed full of rocks? If it’s an aero wheel, for tri bike riding, is it given to frequent, intermittent, stalls in sidewinds? (The 303 Firecrest is designed with precisely this in mind.) It’s a different set of imperatives for me nowadays.

What you’ll see in the 303 Firecrest,

So, I’m biased in favor of the new Firecrest 303, because the old one got me out of a number of fine messes like the one above. Honestly, if they were going to make one mold of the new Firecrest 303 I think they should’ve made it in 650b first. That wheel size is going to be used in women’s proportional bikes (Canyon) and a few other things but if and when it’s used for offroad (gravel) its real benefit is that wide bead diameter. This wheel will be perfect in 650b, though I think Zipp built it first in 700c because it’s going to be a terrific road wheel and it’s aerodynamic value is probably diminished for my preferred 650b use case (53mm Schwalbe G-One tire on my gravel bike).

Anyway, here it is, it’s set up for 1x, with an Eagle 10×50 12sp cassette, with a 40mm Zipp gravel tire.

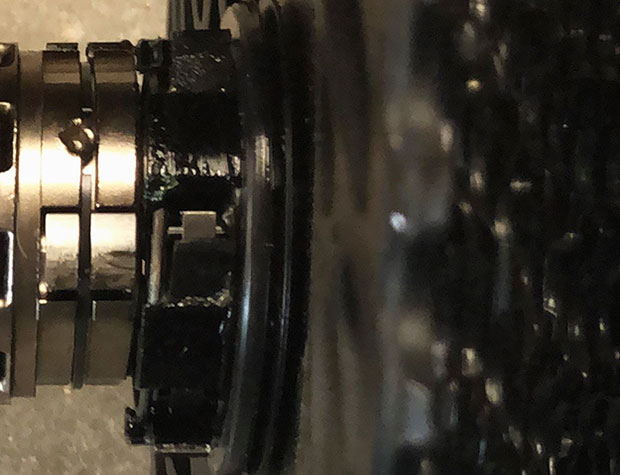

Let’s talk about hubs and driver bodies. The 303 S uses a 76/176 DB Hub. I have no idea what those numbers mean, but I could imagine it refers to diameters. Don’t know. This could be a little unnerving to some of you, but if your thru or QR caps are press-on, as they are on Zipp’s new 303 wheels, you can literally grab that big Eagle cassette and pull the whole thing off the wheel, driver body, cassette, everything. Lots of wheels are like that nowadays. The only wheels that don’t act like that are those with end caps that thread on. (Note: be careful if you yank a cassette body driver off your hub, because you’re liable to have hub pawls flying all over depending on the hub.)

When you do take off the body driver you get a look inside at the cassette assembly. (Which is not the hub assembly.) There’s a lot of good stuff in there. What you see are larger than typical cassette body circumferences. Everything’s larger in these Zipp hubs (except for the XDR driver body, which allows for smaller, 10t, cogs). I don’t know if you can tell from the image above, but the cassette body in the middle, attached to that massive Eagle 12sp 10×50 cassette, is the one that comes on the 303 Firecrest wheel. It’s a LOT bigger than the 2 driver bodies on either side of it. The gold cassette driver is pretty industry-typical. It’s what I got from Saris when I bought an $89 driver that allowed me to put SRAM AXS cassettes on my H3 trainer.

The other driver is the one that goes on the Zipp 303 S. That driver is slightly larger in diameter than the Saris, but not nearly as large as the driver on the hub spec’d on the 303 Firecrest.

Look at this image above, and in gold is that Saris driver. In black, next to it, is the driver on the 303 Firecrest hub. It’s like a garden tractor against a construction tractor.

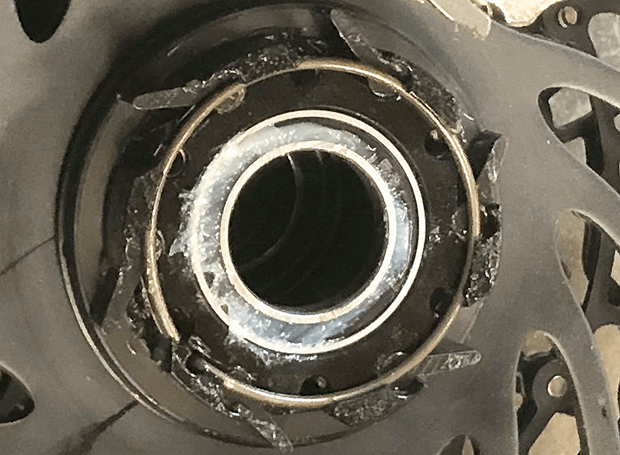

But it’s not just the diameters, which allow for bigger bearings, which of course we’ve already seen in bottom brackets and headsets. There are also more pawls in the more points of engagement.

Above you can see there are 6 pawls in this hub, and more typical are 3 or 4 or, if there are 6, it’s often 2 pawls side-by-side, but the spacing is still 120° apart from each other around the circumference of the assembly. In this case, the pawls occur every 60° around the assembly.

This body driver fits inside what’s called a “ratchet ring” and of course the ratchet ring is likewise oversized. What you see below are the 303 S hub against the 303 Firecrest hub. It’s hard to tell how much bigger the ratchet ring is on the Firecrest hub, but it is, and I dig it.

Let me close by saying that the 303 Firecrest (in particular) is an aero wheel, with a depth of 40mm, which makes this a perfectly good front wheel for a tri bike. This is one of those multi-use-case wheels, where I could easily use this wheel for tri, road, CX (if I did that sport) or gravel. What Zipp says is that this wheel is optimized, aerodynamically, for a 28mm tire. Get used to this. When I began racing, the standard for speed was a 19mm or 20mm tire. Then it got it up to 23mm which furrowed the brows of those worried about the aerodynamic loss from these larger 23mm tires. Over the past 5 or so years the movement has been toward 25mm. Now I think we’re moving toward 28mm, even for timed racing, because folks are now looking at the entire system, factoring in the losses incurred through vibration (both mechanical losses and biomechanical losses in muscle function).

But if your design imperatives call for a softer ride, that means a larger tire. This drives a rim with a larger bead diameter, and this is precisely the wheel you see here. I just would like to segue for a moment, to remind us all that this is what the late Steve Hed was saying more than a decade ago! And this is what drove his product design. Larger, better funded wheel companies – like this one I’m writing about today – were touting their superior engineering capacity, with not-so-veiled insinuations that HED could not keep up. (And now I’m going to curse, because I still have a little heartburn over this.) That was utter horseshit. What we see in evidence today, with Zipp, ENVE and the rest of the world, is that we’re catching up to the notion and benefit of wider bead diameters championed by Steve Hed way, way before this became a thing. But that was then; it was a prior age; other people; I’ve said my piece; time to let that go.

What I’m riding today is a lot of ENVE, Zipp, HED, DT Swiss, a bit of Fulcrum and Profile Design. There are plenty of good wheels out there. The coda on these wheels from Zipp is this: Zipp has learned its lessons well. It learned how to make a gravel wheel by learning how to make a Classics wheel. It learned how to make the ultimate road wheel by learning how to mate the aerodynamics of a timed race (triathlon) wheel to the strength and durability of a Classics wheel. It learned how to integrate the imperatives required by an entire (bike and rider) system, and the evidence is the overall shape and dimensions of this wheel (including bead width).

And then SRAM pushed its daughter brand Zipp toward what SRAM historically does well (and better than Zipp did before it became a SRAM company): It flowed its tech down to more affordable prices, which is what we see with the 303 S (read more about this wheel at SRAM). And, thankfully, Zipp/SRAM does NOT have an attitude(!) and it shows in how this wheel is made. We’re having a discussion right now on our Reader Forum about the merits of Centerlock versus 6-bolt as the platform for disc brake rotor mount. Centerlock is Shimano’s standard. Centerlock is better. These new Zipp 303 wheels are Centerlock.

Not being made of money myself, and because I insist (the great majority of the time) on paying for what I ride (along with paying my own entry fees), I’m in your situation. Money is made of trees, but it doesn’t grow on them. So, bear in mind what I bear in mind: The Pro’s Closet is where you turn your old inventory into cash. This is easy. Go through that process (it’s not just bikes; it’s all kinds of stuff). Get the voucher. Take it to your LBS. Drop your stuff off. Done! (Your LBS will ship it.) Or, transact with TPC yourself. As to these wheels, I bought a set of Shimano SPD pedals from MyBikeShop.com day before yesterday. They’re a partner here, but I prefer to buy incognito, to experience what you experience. I keep coming back to these folks, because I stand in solidarity with them as a Slowtwitch partner, and because if you haven’t bought from them, and you haven’t experienced the “first transaction” with these folks, then you’re in for a treat. Here’s their Zipp 303 S page.

If you’re interested in the 303 Firecrest, whether from MyBikeShop or your LBS or another retailer, my advice is to be very careful when ordering! While the 303 S is new, and cannot be confused with another wheel, the 303 Firecrest is an existing, in-line, model name. The new wheel has no bead hook, is not made in 650b, is a tubeless wheel, and is made in a 25mm bead width. The wheel it replaces is nothing like it. Be careful not to buy the old wheel unless you want the old wheel.

Start the discussion at slowtwitch.northend.network