A man-skills workshop

Cars do not need to be in the garage. Why? Because you're going to sell them as soon as the extended warranties are up, so all you care about is making sure your car's paint job lasts 5 to 7 years. Of course this means you're not only [blank]ing the car, you're [blank]ing its eventual owner, the guy to whom you're going to say, "I cared for it like it was my own dear mother." But in your head you're saying, serves you right for buying used.

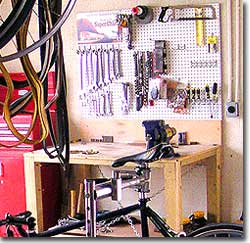

So, now that you've got your priorities straight, and the cars are out of the garage and the bikes are in, how do you set up a workshop? I'll tell you how mine is set up.

I don't have a bicycle workshop distinct from my general workshop. However, it is certainly true that I have storage trays and bins for bike stuff in their own spots. But, if you're a tinkerer, you're a tinkerer, and you'll use your workbench, and bench grinder, your hammer, hack saw, air compressor, hand tools, for all sorts of projects. And this is the basis for a good bike-specific workshop: all the basic hand tools needed for an all-around home workshop.

You'll need a workbench. On top of your workbench is going to be a big, heavy vise, and on this vise you'll be hammering, sawing, wrenching, torquing, banging, and you need that workbench to stay in one place the whole time. So, I built mine out of heavy lumber, with braces and cables and turnbuckles keeping it from flexing in any direction. You can buy a workbench, but then you'd best consider lagging it to the wall, to keep from moving about as you exact abuse on implements affixed in your vise.

Then the pegboard. This is cool, because pegboards give you a great chance to scratch your creative itch, and create patterns for tool display. There's something very satisfying about arranging tools on the pegboard. I put my general tools here, not my bike specific tools. So, open-end wrenches, sockets, screwdrivers, hammers, stuff like that goes here.

Then, right next to my workbench is the big, red stand-up automotive-style toolbox. These are expensive. So, look for a deal on yours. I keep my bike specific tools here, along with drill bits, Allen wrenches, and every sort of wrench (side pulls, wire cutters, pliers, and the like). They have nice ones in Costco and Sam's Club.

Right next to that is my stack of shop rags, and dirty shop rag bin. I do not have a parts cleaner in my shop, because of the waste fluid disposal issue. It's very hard to find a place to get rid of dirty solvent nowadays. So, I don't clean my parts in a parts cleaner, although there is no doubt that this is the easiest way to do so.

If you go to Sam's Club or Costco, or to Harbor Freight tool or similar tool outlet, you'll find those red shop rags for sale pretty cheap. Just don't wash them with your regular laundry, as the red die from the rags leaks, and you'll end up with pink underwear.

Also necessary is a bench grinder, with both a stone wheel and a wire wheel. I use mine constantly It doesn't need to be big. Maybe 1/2 horsepower, no more than 3/4 horse. Shouldn't cost more than about $60. Likewise, an air compressor is nice. Mine is about 3hp, maybe a 20 gallon tank, all mounted on wheels so I can roll it around. It's a single-stage compressor, which means it pumps to 125 psi. This is fine for me. In order to justify anything bigger than 3hp, and/or a 2-stage compressor (which pumps to 175 psi) you'd have to be an automotive tinkerer, with the need to run some big air tools, and maybe you'd have a hoist in your garage (like in an auto repair bay).

I use my compressor for filling up tires (bike and auto). I use it to power my nail gun. I use it for the cleaning value of compressed air. Air gets in places where rags cannot. So, if you want to clean your bike with soapy water, a compressor makes it easy to blow the water out of hidden places. Therefore, the two most important tools you'll need are a presta valve adapter for tire inflation, and a simple air shooter-thinger.

About the only thing I keep separate is woodworking tools. All these are in my workshop, but I never used them in my workshop. I drag my table and miter saws, sanders, and all, outside and use them there. Wood dust and machined parts don't mix, except that a nice patina of oiled wood dust makes for a robust protectant. So, if you want to preserve, and not ride, your bike over the next 20 years, then use your table saw in your garage.

So let's recap, and discuss the typical workshop things that everybody ought to have in every workshop of any sort:

Big stuff:

– Air compressor

– Bench grinder

– Bench vise

– Bench grinder

Hand tools:

– Socket sets

– Nut drivers (hex head drivers that go into your cordless drill)

– Cordless drill

– Torque wrenches (I've got a big 'un and a little 'un).

– Ball-head T-handle metric allen wrenches

– Elbow-style allen wrenches

– Allen wrenches that plug into a 1/2" or 3/8" (socket set) drive

– Open end wrenches

– Hacksaw with 32 threads-per-inch (or finer) blade

– Hammer

– Rubber mallet

– Flat head and phillips head screw drivers

– A nice set of hand files

– All kinds of nice measuring devices (metric yardsticks, rulers, tapes)

– Levels (Sears makes a nice digital 48" level; have another simple 24" level)

Now, let's talk bike specificity. What you want is a nice workstand. I'm a sucker for good workstands. I like a big heavy workstand and I have two — one I bought new, and one I got when a shop went out of business. I know that many people like the Park stands on the collapsible tripods, and they're fine, especially if space is an issue. Just make sure the stand itself, and the system affixing your bike to it, is heavy duty.

The least-duty system I'd buy is Park's PCS-10. This is the "home" stand that is closest to an industrial unit that a shop would use. It also has — so I'm told — a new clamping system that's better for odd-shaped tubes, which most of our bikes now have.

You don't need necessarily to get the whole stand. You can buy stands that bolt onto your workbench. I like the idea of two workbenches, or one long workbench, and one is for your bench vise and the holds your bike stand on one end and a bench grinder on the other (and maybe even a wheel stand in between, if you really want to get down and hinky.

Now, where to put your bikes? Bikes take up a lot of space. Best to just have them out of the way. I built a little framework, lagged to the wall, into which I put those little plastic coated hooks. I hang my bikes on those. If the hooks are 18" apart from one another, you can place the bikes that close to each other, as they alternate hanging from front wheel, then rear wheel. The holes into which the hooks are threaded ought to be about 5'6" from the floor.

This leaves wheels to deal with, and these are also space killers. These I hang up via a another simple frame that extends over the top of some metal racks that contain bike part bins. "I don't have very many wheels," you might say. If you're a bike tinkerer you'll attract wheels like your closet attracts coat hangers. Most important are simply the extra wheels for training.

Space management is the key here. To that end, you need to think about using all the space in your garage. Not just the square footage, but the cubic footage. Storage must be considered as a three dimensional problem. This is why my wheel hangers sit just above my bike hangers: everything above the bikes is dead space, so why not use it? The wheel hooks are offset at a 45° angle from each other. Wheels are triangular, so if you stagger the hubs and skewers you can fit half again as many wheels on your rack.

Save just about everything. Especially bike specific nuts and bolts, ferrules, housings, anything that you can't get at your local hardware store. But categorize them in organizers. And, if you're the sort of person who hates not having things right there on hand when you need them, buy certain items in bulk. For example, I'll buy 50 innertubes and 15 or 20 tires, rim strips, a bunch of gear and brake cable and housing, lubricants, small tools, CO2 cartridges, cassettes, handlebar plugs and tape, during the winter when I don't need it right then. Come December or January I'll get all my wheels out, figure out what tubes are bad, what tires are worn, and put all my wheels in good working order.

"Buying in bulk is expensive," you might say. Not so. Go around to the mail order sites and write them emails and give them your bulk order, see what they're willing to do. You don't need aftermarket packaging or anything. You just want the stuff. So, asking a mail order company for a bulk order of several hundred dollars, without the necessity of aftermarket packaging, and doing so this time of year, might yield you an eyebrow-raising savings (though you might have to email to a half-dozen of these retailers before you find one who's really willing to play ball with you). Be less picky. If these are training tires, don't demand Vittoria EVOs. Be fine with Hutchinsons, Schalbes, whatever. Those are fine tires.

Assemble trays into which will go all your Allen wrenches, each tray representing a size. I've got a million Allens. If they are all sitting in one large drawer what a pain it is to try to find the one elusive 4mm when you've found six or eight wrenches in each of every other size!

Otherwise, my workshop consists of racks and bins where I keep my spare parts. I've got stems in a variety of sizes and pitches, cogs and cogsets, aero bars, pursuit bars, bottom brackets, cranks, and whatever part it is that I've somehow acquired and have discarded or not yet gotten around to using. Hubs, spokes, cable guides, saddles and seat posts. If you tinker long enough, and buy when you find a deal, you too will soon acquire your own stock of bike parts you'll never use in a million years.

One other thing. And this is very important. It's the tool you'll use more than any other. A broom. Actually, you'll need two or three brooms—a hand broom (whisk broom) for your table-top surfaces, a large push broom for the floor, and a corn cobb broom for harder to reach surfaces. And the dust pan. Keep them in a handy place.

This is the basic workshop set up for those who'll work on things other people build. When you're building your own stuff, well, then you need machine tools—a little desktop mill, and a lathe, maybe a heavy duty drill press, and a welder. But then you're treading awfully close to an alternative redneck lifestyle, in which you'll need girly calendars on the wall, 220-volt power, country music blaring in the workshop's boom box, and then it's guns and after awhile you'll lose interest in bikes altogether or anything that does not have its own motor (although my roofer hunts wild boars with spears after chasing them down on his mountain bike, so, put together your own shop as you like it).

We have not spoken yet about bike specific hand tools. That's for another installment.