Empty space finds new traction

The year was 1990 of thereabouts, I was at the Texas A&M wind tunnel with John Cobb and Steve Hed. We were testing products and athletes, and maybe Kenny Glah was there that year, maybe Mike Pigg, maybe Lance Armstrong (all those two-decade-old trips seem to run together).

But there was one fellow at that tunnel test I absolutely do remember, a Seattle bike maker named Dan Wynn. He had the oddest and, truth be told, ugliest bicycle fork I'd ever seen. It was made of steel, the fork crown horizontal and wide. The fork's blades were perfectly vertical, so, if the dropouts were spaced about 108mm apart, center-to-center, the blades were attached at the crown at that same distance.

Ralph Ray (bike biz old timers will remember him) was at A&M as well, and explained it to me this way: "Wynn is trying to get rid of interference drag." Specifically, the problem Wynn was solving is similar to the interference drag created by closely spaced parallel surfaces such as the wings of a biplane. Elegant idea, thought I, especially because Cobb and Hed each had an eyebrow raised when looking at the drag on any bike with Wynn's fork attached.

Shortly thereafter, I came across a very nice cold forged hub made by the Japanese company Sansin, spaced at 80mm (instead of the typical 100mm fork spacing). I believe the hub was made for keirin racing, I seem to recall both the front and rear dropout spacing on keirin bikes was narrower back then.

My thinking was that if I couldn't do anything about the fork blade width (at least in the short term) I could narrow the hub's flange width, and get the spokes away from the blades that way. Sansin's 80mm hub had flanges 60mm apart, center-to-center, instead of the normal 80mm flange width you typically find on front hubs. We had Sansin build the hubs with a normal-length road axle, and a 10mm spacer on each side of the hub, granting the hub normal road spacing.

This worked fine for us because most of our bikes back then were built with 650c wheels. The shorter spoke length was a sensible match with the narrower hub, because the triangulation of the wheel was not that much different than a 700c wheel on a hub with flanges spaced at 80mm.

Pictured above is Felt's new launch: a wheel built around a hub with flanges spaced at 55mm. "But wait!" you might protest. That Felt hub is for a 700c wheel, not a 650c! Where's your triangulation, man!"

And you'd be right. Except this Felt product is not an OE hub for standard training wheels. This hub is designed for race wheels, with deep dish rims. If the distal end of the spoke terminates on the proximal edge of a 80mm or 90mm rim, the spoke is going to be terrifically short, not only giving you the triangulation you need, it's difficult constructing a good wheel with the heaps of triangulation you end up with when you build these wheels around standard spaced hub flanges.

But we weren't done. We were greedy for more "empty space," so, we contracted with Kinesis to build us a fork that we hoped would achieve two things: yet more spacing between the blade and the wheel; and better navigation thru side winds by placing most of the fork's blade depth behind the steering axis.

The fork was introduced in 1996 or thereabouts, was aluminum, was called the Illuminaero, and was a true boat anchor. Heavy, yes, but it worked, and a year later we came out with the Carbonaero. The fork was so good at what it did that both Trek and Cannondale used the fork under license on their tri bikes.

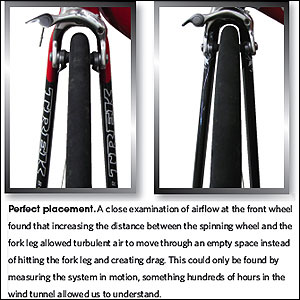

Trek evidently never forgot the idea, and the adjacent pic shows Trek's fork on the new Equinox TTX (along with its explanation).

This causes me to wonder what we might see if we put Felt's wheel inside Trek's fork. That's the sort of thing we did just over a decade ago. HED built us a special set of front and rear hubs, each spaced about where Felt's hubs are spaced now, and we had HED built up a 16-spoke 90mm front wheel, and a 20-spoke 90mm rear wheel. I still believe these wheels, inside of our Carbonaero fork, would stand up to anything built today as regards drag, sensible construction, and handling, and I think it might help explain why so many bike splits on old QR bikes during the 1990s hold up so well today.

We had a terrifically hard time selling any of these wheels. We seemed to convince no one but ourselves of the speed to be harvested from Dan Wynn's idea.

To be sure, "empty space" is not the only way to make a fast front wheel/fork complex. Gary Hooker's legendary time trial bike ascribed to a different theme: make the fork and wheel so narrow, and so close to a single, indistinguishable construct, so as not to offend the wind. But Hooker's bike was very nuanced and, as I recall, the fork dropout spacing was narrower yet, at 60mm.

Now it seems "empty space" is back. Let's see what the cycling world decides to do with it.