Magura RT8 brake How-To

I had an odd request for Cervelo. I don’t want a bike. Just send me the brakes – ONLY the brakes – from the P5. Cervelo put me in touch with the good folks at Magura who make this brake, called the RT8.

What’s the big deal with the RT8? It’s hydraulic. Meaning – there is no brake cable to actuate the caliper; it uses fluid to do the job (similar to your car). They are also the norm on modern mountain bikes. Hydraulic brakes bring a few key advantages to bicycles:

1. The system is closed to the outside environment. There are no brake cables to get dirty and sticky over time.

2. They tend to offer better modulation and feel. In layman’s terms, there is a larger zone between “zero braking” and full wheel lockup. That is generally accepted as a good thing.

3. They have the potential to be light weight.

4. For triathlon – and this is a biggie – they open up a potential world of possibility for aerodynamic brake design. If you want to place the brake in an odd location, cable brakes have a tendency to lose their ‘feel’. A hydraulic line doesn’t ‘care’ where it has to go and there is no cable to get kinked.

All of those things sound great to me. However, I always ask two questions: 1) Does it work? 2) Do the benefits outweigh the costs?

This in mind, I wanted to get my hands on the system and install it on a bike. The RT8 mounts to any standard frame or fork with a single brake bolt. I wanted to approach this as though I was a consumer wanting to upgrade an existing bike with an aftermarket RT8 brake. In my experience, this is always the more difficult path; stock bikes normally have some measure of installation done for you ahead of time (i.e. internal cables routed, etc). How difficult is the RT8 starting from scratch? Let’s find out.

Getting Started

The brakes came to me in two separate boxes; one front and one rear.

Note that the front and rear calipers are the same – and the levers are the same – it’s just the line length that differs. Both lines were generously long to accommodate all sizes of bikes. You will need to shorten them.

Also note that the brakes do NOT include pads, pad holders, or any pad hardware. You must source this on your own. Magura representatives told me that they are working on their own design for this, which will be included in the future. I was unaware of the lack of any pad hardware when I received the brakes, so I resorted to rummaging around in my parts cabinet. I ended up finding enough SRAM Force pad hardware to spare, along with Zipp’s now-discontinued Carbon/Carbon pads (which, incidentally, is still one of my favorite pads for alloy rims).

To start this party, we need to run the lines through the handlebars and frame (if applicable). Note that your base bar MUST support internal cable routing to use the RT8’s.

Magura says that you should always trim the line from the caliper end; do not trim from the lever end. To remove the line from the caliper, unthread the bolt with an 8mm open-ended wrench:

Pull the line out and set the caliper aside. Trim about one or two inches of line from the end – you will cut off the hardware on the end. I used my heavy-duty Avid shop-grade line cutter, but a flat razor will work just fine.

Next, insert the line through your base bar. Mine is a Profile T2+ aluminum bar, and has a housing exit hole towards the back of the hand grip area. The hydraulic line is fairly rigid, so I had to insert a piece of 2.0mm spoke in the bar (to find and guide the line):

Push the line all the way through and insert the lever in to the bar. You tighten it in place via two small 2mm bolts hidden inside the lever (one on either side):

NOTE: As you’re routing the housing, it is a very good idea to wear shop gloves, glasses, and an apron. With the line being so rigid, it tends to flop around and fight you – and spray drops of oil at you.

Next, install the caliper on to the bike. Don’t go crazy tightening it down – you will have to remove it again later. This step is only to help cut the line at proper length.

This is also the step where I realized that I was going to have to improvise a little bit:

My traditional external headset interfered with the line bolt. I found a second washer in my parts bin, which allowed me to space the caliper forward by a few extra millimeters.

However long you cut the line is up to you. If you install the RT8’s on an existing bike (that fits you), cut them as you normally would. If you still have potential fit adjustments to make, my advice is to leave the lines a little bit long. It is always easier to trim them later than to install a completely new line.

Once your final cut has been made, it’s time to install the line fittings that we cut off earlier. First, remove the caliper. You should reuse the 8mm bolt, but do NOT reuse the olive. Magura supplies a couple spare olives with the brakes specifically for this purpose. Their design – like many hydraulic bicycle brakes – relies on this one-time-use item to be crushed when you tighten the bolt, making a tight seal.

Be sure to apply light pressure down on to the line as you tighten the 8mm bolt. In the right photo above, you can also see my washer stack to space the caliper away from the headset. Once the line is secure, you can bolt the caliper to the frame/fork for the final time.

Now it’s time to bleed the brake. Why bleed brakes? The process of bleeding removes any air bubbles from the system. Unlike liquid, air can be compressed. If you have air bubbles in the line, your lever will feel mushy as you squeeze it – you are compressing the bubbles instead of moving fluid. Bleeding is extra important on the RT8 system because it is completely closed. There is no fluid/air reservoir to catch bubbles (unlike most mountain bike brakes). The master cylinder pushes directly on fluid, which moves the caliper piston.

Before you begin bleeding, Magura recommends that you tilt the bike down slightly to position the brake levers in a way that avoids air bubbles. If your base bar tilts up like my Profile-Design T2, you should tilt the bar down more than a base bar with flat grips.

My work stand attaches to the bike at the fork and bottom bracket, so there is no real way to angle the bike. What to do? Improvise:

Magura makes two versions of their bleed kit – the ‘Small’ bleed kit, and the ‘Pro’ bleed kit. I got the small kit.

This is the part in the demo where the “expert” (me) screws up. Yes, it happens to the best of us. The good part for you is that you can read about my mistakes and avoid them yourself. The small bleed kit includes two syringes and two hoses. YOU ONLY NEED ONE HOSE. Do not use two. One syringe should be set up with a hose and plunger – seen on the right in the above photo. The other syringe should be set up sans plunger and hose. I have it half right – the plunger is out, but the hose is there. We’ll explain this further in a minute.

Take out your first syringe, stick the hose in your fluid bottle, and fill it up to about the 25ml mark. Then, turn the syringe upside down to let the air bubbles rise, and push them out. You’ll want to wrap the end of the tube in a paper towel to catch any fluid that sprays out.

Magura recommends ONLY using their Royal Blood mineral-based oil. Do NOT use any type of DOT fluid. Some people argue in favor of DOT fluid because of its higher boiling point. The problem is that it is hygroscopic, meaning that it attracts and absorbs water. When that happens and the fluid degrades, the boiling point and performance of the fluid drop (unlike mineral oil). That being the case, most DOT-based bicycle systems recommend that you change the fluid out every year or so (automobile fluid change intervals are somewhat longer due to the higher volume of DOT fluid, but still require fluid changes every 2-3 years). Magura’s Royal Blood has a boiling point of 358 degrees Fahrenheit. In comparison, DOT 3 fluid boils at 401 degrees when brand new, or at 284 degrees when it has approximately 3% water in it. For triathletes (who may not work on their bikes very often), I think this fluid choice was the right one.

While we could proceed with the bleed from here, I like to do one extra step – I ‘bleed’ the syringe. Put your finger over the end of the tube and pull down on the plunger. You’re creating vacuum. What this does is make any tiny hidden air bubbles make themselves known:

Once those air bubbles rise to the top, push them out. I repeat this process a few times.

Next, push the barb fitting in to the end of the hose:

Push a little bit of fluid out so you know the hose is completely air-free.

Now, remove the bleed port screw on the caliper with a 3mm allen key (not shown), thread the bleed syringe in, and squeeze the top of the caliper to ensure the pads are fully opened:

Next, make sure that the 2.5mm hex bolt at the caliper is backed out all of the way. It will NOT fall out, so don’t worry. This is a manual adjuster for the master cylinder, and adjusts the width of the caliper (to accommodate different rim widths). Due to the closed nature of the system, this must be completely backed up before bleeding. If the bolt was dialed in and you bleed the system, the brake would function fine – unless you ever back the bolt out (i.e. for a wider rim). There would not be enough fluid in the system and the lever would feel mushy.

You can also open the brake quick release, shown on the right (the red dot shows its point of origin):

You do not actually need the QR to be open. This was one point where the instructions were not clear. The small manual included with the brakes says to open the QR – but does not mention when during the process to close it. The YouTube video of the brake bleed leaves the QR closed the entire time. I inquired with Magura directly, and they mentioned that you can do it either way, but they generally recommend leaving it shut.

Now we need to attach the top syringe to catch fluid at the lever. Remove the EBT screw from the top of your brake lever with a T25 Torx.

Notice that I have a hose going in to the lever. What you’re supposed to do is insert the top syringe (without the plunger) directly in to the lever – without a hose. This is another point where the instructions tripped me up. The YouTube video only shows how to use the Pro bleed kit (not the Small bleed it), which uses a hose and special adapter nipple to fit into the lever port. The printed instructions that come with the brakes have a very small and grainy photo of this part, and I couldn’t tell what to do. The bleed port is threaded, so I thought my bleed kit might be missing a part. Hmm.

The supplied hose almost fit in to the bleed port, but not quite. I happened to have some ¼” vinyl tubing handy, which was more flexible than the stock tubing. I cut a piece of this, smashed one end down with pliers, and managed to jam it in to the lever’s bleed port. It was difficult, but actually sealed quite well.

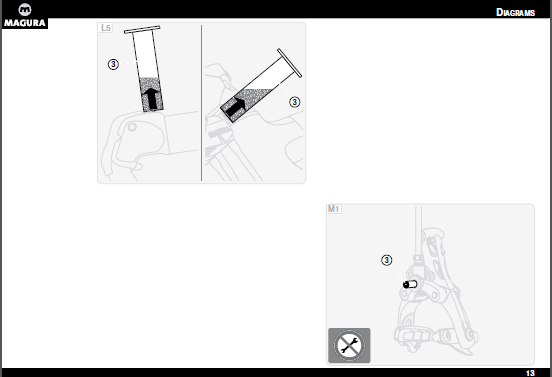

I later found a third set of instructions online in PDF form, which include a graphic for what you’re actually supposed to do with the cheaper bleed kit:

Oops. I spoke with Magura after-the-fact, and they said I wasn’t the first person who had done this – and that they intend to update the printed instructions to be clearer.

Regardless of whether you use the syringe, the Pro bleed kit, or my jury-rigged bleed kit, the next step is the same – start to push fluid from the bottom syringe:

You will see fluid and air bubbles start to come out in the top syringe. As you push fluid, flick the brake lever a few times with your hand to break loose any sticky air bubbles.

Most mountain bike brake systems rely on a more complicated bleed procedure – often with vacuum created at both the lever and caliper. The nice thing about the RT8 system is that the inner diameter of the hose is quite large – 2.5mm, vs about 1.5mm for most MTB systems. This means there is a much smaller chance of air bubbles getting caught in the lines – so you don’t need as much vacuum on the line for bleeding.

Once the air bubbles stop, you can disconnect the top syringe. Note that if you do not have the Pro bleed kit, there is a 100% chance that you will spill fluid while removing the syringe. Be prepared with paper towels and do not wear nice shoes. My fashion-forward Crocs fit the job perfectly.

With the top syringe out, replace the EBT port screw with your T25 Torx. Then remove the bottom syringe and replace the 3mm bleed port screw.

To test the system, squeeze the lever. You should see the caliper move immediately. If there is any lag time, the bleed was not done properly.

Assuming the bleed was successful, you need to adjust the pad width to match your rim width. To do so, simply thread the 2.5mm hex bolt in the front of the lever. This pushes the master cylinder, which pushes fluid, which pushes the caliper piston – and moves the pads closer to the rim.

The 2.5mm adjuster works well, but I found a potential problem when using a narrow rim. My front rim, for example, is a 20.5mm Shimano C24 clincher. It’s not super wide, but also not as narrow as the 19mm rims of yesteryear. As you bring the pads close to the rim, the caliper spring tension goes down. I found that when I had the lever throw where I wanted it, the spring was quite soft – resulting in a slow return. Magura says that this can be remedied by using one or more small washers between the caliper arms and brake pads (similar to what other modern TT brakes do). The only problem is that none are included with the brake. I didn’t have any in my parts bin, so I’m left with a brake that feels softer than I’d like.

As far as hydraulic brakes go, the design is very simple. That being said, I’m guessing this installation and bleed is more complicated than about 80% of triathletes want to deal with. That’s not a deal-breaker, however, as many bike shops have the tools and experience to install these brakes. If you are a retailer, I advise that you invest in the Pro bleed kit, as it will make your life easier. The bonus is that once the brakes are set up, they’re essentially maintenance free. Magura guarantees the fluid for at least five years. You still likely want to lubricate the pivots every once in a while, but that’s no biggie.

My only real beef with the brakes is the fact that they don’t include pads, pad holders, or washers for spacing them in. With a wider rim on the bike, I found the lever feel to be much improved. Magura says that the lever itself was designed with aerodynamics in mind, which makes sense for the application. I personally would like to see a lever that is 1-2cm longer, and sweeps away from the rider towards the end of its length. The current lever is completely flat, and does not suit my preferences for a secure feel (i.e. on rough pavement). With my base bar, I can only reach the lever with my index finger. Of course, the reach and shape of your base bar highly affects the reach to your brake lever; other bars may improve this part of the experience.

I have a feeling this isn’t the last we’ve seen of hydraulic road rim brakes. For all of you P5 owners out there, do you like the feel and function of your RT8s? If you do not own a P5, would you consider upgrading your existing bike to RT8 brakes?

Start the discussion at slowtwitch.northend.network