Not Such a Dumb Idea After All

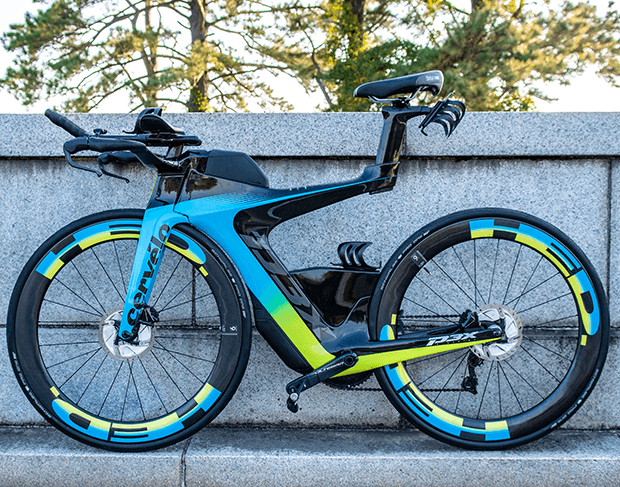

New tech in cycling is like a lottery draft pick. Most enjoy success, some spectacularly so. A few flame out, some spectacularly so. Aero bars and steep seat angles stuck around. Beam bikes, less so (I remember when Softride was #3 in the Kona bike count). The Cervelo P3X (below) is a terrific bike. Sometimes really good tech nevertheless struggles at the cash register (e.g., smaller wheels for smaller riders). How do you know when new technology benefits you and will stick around; or will quietly disappear?

I’m building up a bike in my workshop and what is so striking is how easily it goes together. This is an electronically shifted bike, parts made by SRAM in this case, and I’m so thankful that I don’t have to fish shift cables through the frame and then try to get the derailleurs to shift adequately. The only thing that’s semi-new in this process – and I have to always remind myself to break this very old habit – is that you can’t begin by installing the BB and crankset. This used to be the initial part of a build and it was very satisfying to get the heart of the bike into the frame right away.

You can’t do that nowadays because the one line that spans the inside of a bike is the rear hydraulic brake line and you might not be able to get it past the BB. So, you run that line to the rear brake caliper and then you can install the BB and crank. That crank is getting easier to install for reasons I’ll get to in a moment.

Bikes – at least road and gravel bikes – just go together so easily nowadays. It does make buying a frame and building it up in your own workshop feasible. But you must have certain skills and I suppose chief among them is brake bleeding. And, the tools and materials.

If you’ve gotten this far you’ve maybe noticed a couple of things: first, how easy it is to build a bike; second, the one hitch in the get-along, which is the whole brake bleeding business. Here is what I want to impart to you today: Yes, there is such a thing as a bad idea masquerading as a technological step forward. Let’s go over some “new tech” but I want to remind you that long before most of you started cycling we’ve had these “new tech” debates. I remember the year Shimano mugged Campagnolo and I don’t know how else to put it. The venerated Italian brand went from mandatory spec to dropped like a bad transmission in 1 year (maybe 1984 or thereabouts?). The debate – which was short – was whether click or “index” shifting was a good idea. Prior to this, gears worked by “friction” shifting. Imagine the frets on a guitar not being there.

Fast forward 2 years to the Kestrel 4000, the world’s first monocoque carbon bike. Do you know who bought this bike first? Not road racers! Not going to be seen on that plastic bike! It was triathletes who embraced this new tech (notwithstanding the Campagnolo parts on it in this pic). Which is to say, show me new tech and I’ll show you resistance to it.

Here are some examples of tech that has popped up over the past 30 years:

Tubeless tires

Hookless beads

Electronic shifting

Machined cranks

Disc brakes (in road and tri bikes)

Press fit bottom brackets

Integrated stem/bars

Completely hidden hydraulic lines

You’ll notice that some of this tech doesn’t exist on your bike. Why? Because not all new tech is good tech. The most obvious bad idea in this list above is machined cranks. It turns out that cranksets need to be made of one of two materials: forged aluminum or carbon. If you machine a crank out of an aluminum billet that crank is not sufficiently strong to withstand the forces of cycling. We found this out in the 1990s and on some of our bikes we placed these cranks (such as the bike in the image above held by young Mr. Scott Tinley). You could machine as a secondary process but the aluminum had to be forged or the crank risked failure.

In the bike I’m building now the bottom bracket threads into the frame. A number of threaded standards exist, including T47. This one I’m building now is a DUB BSA standard. Of the 5 bicycles I own I don’t believe any of them has a pressed-in BB. It turns out the old tech of threaded BBs is just better and I base this simply on what I see manufacturers doing. But pressfit was all the rage 5 to 15 years ago.

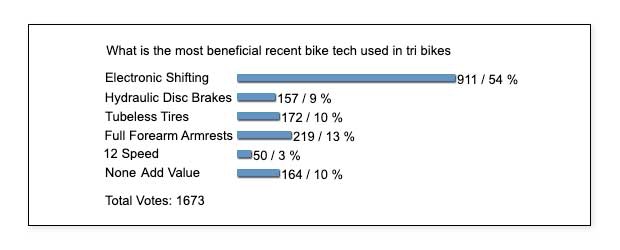

There will always be naysayers. We just took a poll and about 1,600 of you participated. In this poll I asked what new tech you like the most and most of you said electronic shifting. About 1 in 10 of said that you don’t like any of the new tech listed in the poll but if you look on our reader forum or on any social media you would think a majority feel that way. Why? Because naysayers must naysay. Loudly. Those who don’t feel the need to complain stay silent.

The poll doesn’t lie. The silent majority likes new tech… when it works! So, according to me, what works and what doesn’t among all this new tech?

What Recent Tech Will Go the Way of the Pressfit BB?

Integrated stem/bars

Stem-buried hydraulic lines

Hey Trekkies! When the shyte really got brown on the Starship Enterprise and something had to give, what did Captain Kirk do? Reluctantly for sure. But, yes, saucer separation! I’m just a simple country doctor, Jim, but if they couldn’t leave that fatally damaged warp core behind, then, thar she blows! (“She” being the entire ship.) This is exactly analogous to integrated stem/bar front ends. (Well, somewhat analogous.) I predict this is today’s version of the pressfit BB. Seemed like a good idea at the time. But let me just ask you this: motorcycle saddles aren’t height adjustable, are they? Would you like that for your bicycle? Would you buy the bike if the saddle height (and fore/aft) was only in the general range of correct? No? Then why will you buy a bike where you can’t saucer-separate the handlebars so they be adusted fore/aft and up/down?

If you do have a separate stem and handlebar great, but if you run the hydraulic lines through the stem you’ve effectively made the bike unadjustable and I just refer you above to the brake bleed thing. Bikes are very easy to work on today except for that. If your hydraulic lines pass immediately underneath the stem they are effectively hidden. But you can easily change the stem! Adjust your cockpit length and height. And… you still have a clean front end. This is what Cervelo does with the Soloist and R5 road bikes; what Specialized does with the Tarmac; what Cannondale does with its Knot system on its fancy high-end road bikes. The saucer separates! Just like the Starship Enterprise. But like that starship you don’t see hydraulic lines if that's the look you're going for.

What Recent Tech Will Remain and Prevail?

Electronic shifting

Disc brakes (in road and tri bikes)

It seems unimaginable that we had a dispute about this and, look, I remember back in the 1990s sitting on the side of the road with my friend Pete Penseyres, his Mavic Mektronic rear derailleur in pieces all over the asphalt as we were putting it back together mid-ride. It took another decade before Shimano’s Di2 was ready for all of us to use it and – here’s a stat for you – in the 15 years I’ve been riding that system I have never derailed a chain from that system.

Disc brakes in road bikes, I first rode these in April of 2013. This was a SRAM product and to tell you how far back this goes SRAM upgraded to hydraulic disc brakes and moved from 10- to 11-speed at the same time. Yes, this tech had its hiccups. That product was recalled by the end of that 2013 year. But it didn’t stop progress and look where we are today.

What Will Also Remain and Prevail

Road tubeless tires

Tubeless? Oh, man, jank city in the beginning. As opposed to Shimano’s electronic shifting – which was an immediate and unqualified success on my bike – road tubeless took 20 years to get from launch (Mavic’s UST system in 1999) to decent functionality (Schwalbe’s Pro One relaunch in 2019 and the ETRTO’s standards for road tubeless that same year).

Hookless? I think I’m pretty good at knowing what’s going to stick and what’s not. My predictions: 1) that hookless will remain with us and; 2) that integrated, unchangeable front ends will go away are pretty unpopular views that I hold. Let’s talk in 3 years.

If you take anything away from what I’ve written above, I hope it’s these two things. First, that new tech generally works, and the naysayers will always shout their nays at 10x the volume of everyone else, usually laced with a heavy dose of snark and sneer. Second, not all tech does work and the sage user learns to parse wisely. Is there a one-liner that offers reliable guidance? How about: Does this new tech offer the promise of improved performance without causing even larger problems? I know that’s not much. I use that phrase to justify my dislike of integrated road cockpits. Others use that same axiom to argue against hookless rims.

New Tech Only Blossoms Inside a System

I acknowledge what you might label an inconsistency in my thinking, to which I reply: Over the last decade one new tech arcs over all the others and that’s disc brakes. You don’t get the complete makeover of bike motifs without disc brakes. This tech allows frames, forks, wheels, tires all to be reimagined and all to work together in concert. The only times this ever happened during my 40 years in this industry were, first, the remaking of the stem through a pair of innovations: 1) a 2-piece faceplate and 2) the threadless headset; and second, with the advent of the aero bar.

I guess you’d say I’m wired to think in terms of systems, as one of the design motifs for which I have some mild celebrity is the steep seat-angled tri bike and that frame makes absolutely no sense unless you pair it with the aero bar. The aero bar makes limited sense until you pair it with the tri bike frame (like the Quintana Roo Zero Gravity, a bike we made circa 1990 and pictured above). The aero bar was – according to the large majority of pure bike racers and those who manufactured bikes for them – a dumb idea when it came out in 1987. I think we can agree it wasn't such a dumb idea after all.

Start the discussion at slowtwitch.northend.network