The Small Cog Conundrum

When I started to get serious about cycling, high-end road bikes had 9 gears in the rear cassette cluster (say, from Ultegra-level and up). The smallest cog size out back had 11 or 12 teeth. The smaller the cog, the taller your gearing (i.e. the faster you can go). If you were doing flat races, you used an 11-23. For hills, we had 12-25 and 12-27. Yes, there were a few other options, but these were by far the most common.

For the most part, we all had big chainrings up front – 53/39. The front chainrings work in the opposite manner of the rear cassette – more teeth means taller gearing. In other words – if you want to go super fast, you want a BIG ring up front and a very SMALL cog in back. If you want to go super slow (or up steep hills), you want a SMALL ring up front and a very BIG cog in back.

One more item to set the stage: Adding or subtracting a tooth from the cassette makes a bigger difference in your overall gearing than adding or subtracting a tooth from your chainring. Going from a 12 tooth cog to an 11 will give you more “oomph” than going from a 53t chainring to a 54t.

Is that clear? Good.

The Small Cog Conundrum

What I’d like to talk about today is the evolution of the smallest cog size in your cassette. It has changed over time. With more single chainring drivetrains and 12-speed components on the way (i.e. 12 gears in the cassette), things have gotten a bit murky. We’ll talk through the issues in this article, and propose some solutions towards the end.

When we started adding cassette cogs and widening cassette gear ranges, that 12 tooth small cog began to go away. When we evolved from 9 to 10-speed systems, people wised up and said – rather than have the limited range of an 11-23 or 12-25, why don’t we put them together and make an 11-25? All you have to do is tack on an 11t cog to the 12-25 – or a 25t cog to the 11-23. You get a wider overall gear range. With 10-speed systems, you could still find some cassettes with a 12 tooth small cog, but they became less common.

Then – as we seem to do every five to seven years – we added another gear. 10 cogs weren’t enough, so we went to 11. With that change, virtually every cassette on the market standardized to 11 teeth in the smallest cog. With 11 total gears, fantastic new ranges became available, such as 11-25, 11-28, and 11-32.

Then something happened. Single chainring (1x) systems arrived first for mountain bikes, but eventually for road and triathlon, too. These systems make up for the lack of gear range up front by having a VERY wide range cassette out back. SRAM broke ground with a 10-42, which you can see here:

This is a very cool concept, but it’s not without its consequences. First, that 10 tooth cog will not fit on a standard freehub (a.k.a. cassette body – the part of your rear wheel where the gears attach). SRAM created a new design for this, called the XD driver (pictured below). This isn’t good or bad per se – it just means that most older wheels won’t work with it.

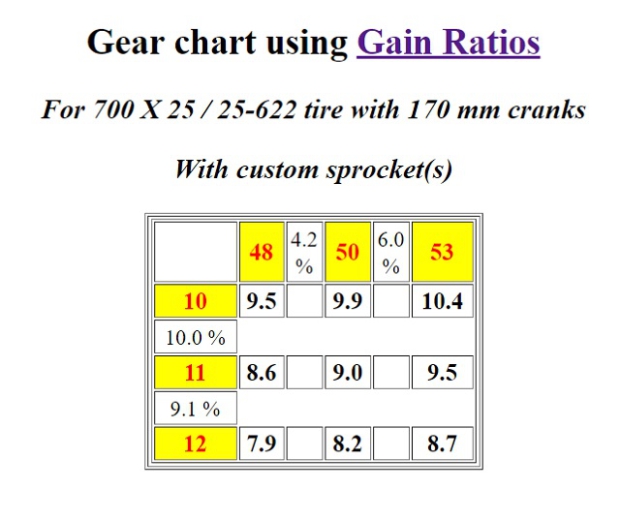

The other consequence is that the 10 tooth cog gives a substantial boost in top-end gearing – to the point where you should use a different size chainring in front. This chart is from the late-and-great Sheldon Brown’s online gear calculator. On the left side, I put three small cog sizes – 10, 11, and 12. On the top, I put three front chainring sizes – 48, 50, and 53. The middle of the chart (white boxes) shows the output in Gain Ratios, assuming a 170mm crank and 25mm tire.

First, let’s focus on the 53 x 11 and 53 x 12 gears. These are the old “standards,” netting 9.5 and 8.7 gain ratios, respectively.

When we move to the 10 tooth cog, you can see that the chainring must go all the way down to a 48 tooth size to match the same gearing as the 53×11 (9.5 gain ratios). If we kept the giant 53 tooth cog, most people would have much more top-end gear than they’d ever use.

So, What’s All The Fuss?

Big deal, you say. Use a smaller cog out back – and use a smaller chainring up front to compensate. It’s easy. Yes and no.

The problem is the lack of standardization. Thus far, 11-speed single chainring drivetrains have waffled between the 10 and 11-tooth cog. Say you normally ride a SRAM system with a 50 tooth chainring and 11-36 cassette. But then you have a race on your calendar that’s super hilly. You decide to go big – all the way to the 10-42. Suddenly you need a new freehub for your wheel and a new chainring up front. It’s not an insurmountable problem, but it will likely cost you a few hundred bucks and a trip to the bike shop. If you only need to make this switch for one race, I’d suggest avoiding the 10 tooth cog, and buying an 11-42 cassette from Shimano, or SRAM’s lower-end 1130 series (it’s a little heavy, but won’t require changing out wheels or chainrings). SRAM does not currently offer 11-42 in their lighter weight components.

So we went from 12 and 11 tooth cogs to 11 and 10. That jump to 10 teeth gave us a bump in gearing that’s significant enough to require new chainrings – not the end of the world. Then came the next step – companies such as 3T and 3*thirteen brought out a nine tooth small cog.

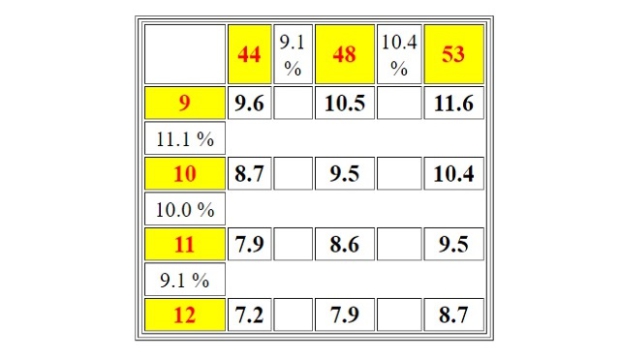

Take a look at this gearing chart, and you’ll see that we have to reduce the front chainring size all the way down to 44 teeth to roughly match the top-end gearing of the old 53×11.

I want to be very clear that there isn’t an inherent problem with 9 and 10 tooth cogs. I love to see out-of-the-box thinking. We all know that technology will evolve.

The issue is the practical integration of the new technology. We’re still in the fits and stubbed toes of its infancy. This seems to have been one issue in the dissolving of the Aqua Blue pro cycling team – the first professional continental team to use single chainring drivetrains. While there were surely other contributing factors, our reader forum dissected the technical aspects in depth .

In short, the mechanics complained about all the extra work. I’ve attended major ProTour races representing a sponsoring drivetrain manufacturer, and I can tell you first hand that pro mechanics have the hardest job of anyone. The hours can be brutal. They clean and tune all of the bikes, they glue tires late at night, they wash the team cars and busses. They charge drivetrain batteries, double check fit coordinates, and wrap hundreds of rolls of bar tape. It’s unrelenting.

Below: 3T's 9-32 cassette.

With a double chainring system, mechanics could often leave the same exact gearing on for multiple stages. Yes, 2x systems may have some redundant gears that don’t get used on a particular stage, but… so what? They also never use a 9 or 10 tooth cog, eliminating the need to change the rear wheel’s freehub when they do decide to change the cassette size (i.e. move from an 11-25 to an 11-28).

With the single chainring bikes, all of a sudden chainring and freehub swaps became a daily occurrence. Say it’s a flat stage – you want a tight-range cassette. You pick an 11-28, with a 53 tooth chainring. The next stage is steeper, so you pick an 11-36, keeping the 53 tooth chainring. The next stage is extremely hilly, requiring a move to the 10-42. New chainring, new freehub, new cassette. For the next stage, the 9-32 is most appropriate – new chainring, new cassette. It seems that rinsing and repeating this procedure was taxing – not to mention repeating the process for the spare bikes.

Solutions

I don’t want to sound like doom-and-gloom, and fortunately there are some relatively easy solutions to make this issue go away. I will present two such solutions. First, my pie-in-the-sky utopia solution, and second – the realistic solution.

Pie-In-The-Sky Solution

If I was king, my solution would be to standardize the industry to a 10 tooth small cog size as we transition from 11-speed to 12-speed drivetrains in the coming year or two. If we could all agree on this, we’d easily establish standard chainring sizes up front for both 1x and 2x drivetrains. Lucky for us, SRAM features a 10-tooth small cog on their new 12-speed mountain bike drivetrains, and Shimano’s 2019 XTR 12-speed mountain drivetrain (pictured below) does the same – though with their own freehub design.

If you want the same top and bottom gearing as a 11-speed 53/39 crank and 11-28 cassette, you’d want a 12-speed 48/38 crank and 10-28 cassette. Easy-peasy.

Realistic Solution

Two manufacturers already make 9 tooth cogs, and the realistic side of my brain knows that they’re not likely to back out. That’s okay, because the next solution will probably happen over time with increased investment from manufacturers driven by consumer pressure.

It’s simple: create more cassette size options for a given small cog size. If you’re SRAM, you go beyond the 10-42 by adding a 10-36, 10-32, and 10-28. If you’re 3T, you add a 9-28 and 9-36 in addition to the existing 9-32.

If these companies expect to have better acceptance of single chainring systems and new 12-speed components, they need to remove the hurdle of chainring and freehub swaps being tied to cassette size swaps. It’s that simple. And I think we’ll get there. Technology is great, but only insofar as you can integrate it into your life. I have a feeling that I’ll have a road bike some day with a 12-speed 10-32 cassette and a 46 or 48 single chainring up front.

Start the discussion at slowtwitch.northend.network