Tires and wheels for timed cycling events

Wheels and tires…tires and wheels. These two pieces of cycling equipment generate a lot of questions on internet forums dedicated to cycling. Every bike has them and every bike owner uses them, selects them, buys them, and even repairs them. Obviously, they go hand in hand; a tire isn’t much use without a wheel, and vice versa. If the frame of a bicycle represents the “heart” of a bicycle, it can be argued that wheels and tires represent the “soul”. Perhaps that’s why opinions about these pieces of equipment can be strongly held…almost with a semi-religious fervor in some cases. When people talk about the “feel” of a piece of cycling equipment, that’s an almost emotional connection they’re describing.

In a series of articles, I intend to explore some of the myths, facts, and test data available about tires and wheels for cycling. I’ll be concentrating on the type of equipment that is used for timed cycling events (non-track) such as in Triathlons and Time Trials. My hope is that at the end of the series, the readers will have gained enough understanding and insight that they can make informed decisions for themselves about their wheel and tire equipment choices. It’s one thing for a writer to list out a bunch of equipment and rank them according to whatever criteria he selects; it’s quite another thing for the writer to explain the background for the “judging” criteria and then allowing the reader to select the equipment that best meets his or her needs. To me, that’s important, since the ideal equipment may be different for various people based on how they prioritize attributes like performance, cost, and durability.

So… let’s get crackin’. This first article is going to be dealing with tires. It’s a big and controversial subject and should be a lot of fun.

TIRE PRIMER

What’s the big deal about tires? A tire’s a tire, right? There’s no big difference between tires except for how they much they weigh and whether or not they cut or puncture easy, right?

Well, when you’re talking about selecting tires for use in a timed cycling event such as a time trial, or the bike leg of a triathlon, it’s not that simple. After all, what is the measure of how one “performs” in these events? That’s right, it’s SPEED. For a given rider power output on a flat or rolling course, after aerodynamic drag the next largest impediment to speed is the rolling resistance of the tires. What about going up a steep grade, when aero drag is minimized and you’re working against gravity? Once again, rolling resistance is the second largest resistance, this time behind hauling your mass up against gravity. Obviously, if one can reduce the amount of rolling resistance JUST by the tire they decide to buy, this is money well spent…you’ve got to buy tires anyway, and the difference in prices between tires is well worth the potential difference in performance. In fact, some cheaper tires (and tire “types”…we’ll get into that later) give better performance than more expensive options.

Oh, come on. Do you mean to say that what tires I run on my wheels can make an appreciable difference in my speed? We’re talking seconds here, right?

Yes, the differences ARE appreciable, and are measurable. In most cases, when talking about the worst rolling tires vs. the best, differences in performance can be measured in minutes, even for events as short as a 30-40K time trial. In my book, that’s not something to ignore…especially if there is little extra cost (if any) to choosing the faster equipment. This truly is a case of “free speed.”

I don’t get it. How can that be? How do I know what a “fast” tire is vs. a “slow” tire? What causes this?

Ah… well, it’s all really simple actually. The rolling resistance of a tire is the result of one simple process; energy dissipation in flexing materials. I’ll try to explain:

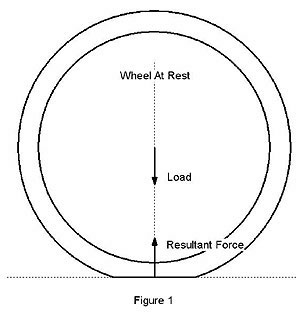

Think of one of the tires of a bicycle at rest. The contact patch of the tire is distorted until the area of the contact patch multiplied by the air pressure is equivalent to the load that the tire is supporting. Increase the load, or decrease the air pressure inside the tire, and the contact patch area will grow…and vice versa. In this case, where the tire is not rotating, if you were to sum up the total force in the contact area, it would be equivalent to the load being supported by the tire. Additionally, the force of the whole contact patch area could be replaced by a single force that is acting upwards through the center of the axle. Look in Figure 1 for an example.

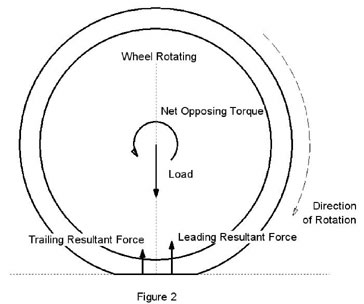

Now, what happens when the bike starts moving and the tire begins rotating? If you split the contact patch with a vertical line that passes through the axle, you’ll find that the pressure in the leading portion of the contact patch (i.e. the part in front of the axle) is slightly higher than in the trailing portion. In the leading portion of the contact patch the tire is being compressed from zero distortion to maximum distortion

In the trailing portion, just the opposite is occurring and the tire is, in a sense, “returning” the compression force to the road surface as the tire “lifts away” from the point of maximum deflection. This difference in total force between the leading and trailing portions of the contact patch is the direct result of energy dissipation in the tire structure. In other words, when the tire is compressed in the leading portion of the contact patch, a portion of the energy applied is dissipated (through processes such as internal friction) in the tire structure. Like in the example above, if we replace the overall force in the leading and trailing portions of the contact patch with 2 equivalent forces, one for each section, you’ll see that the force corresponding to the leading portion is larger than the trailing portion and is offset forward of the axle just as the trailing force is offset rearward of the axle. As shown in Figure 2, these offset forces causes torques about the axle, with the rearward portion causing a torque in the direction of rotation, but with the forward portion causing a larger torque in the direction opposite the rotation of the wheel. The difference between these 2 torques results in a net torque opposing the direction of wheel rotation. It’s THAT resultant opposite torque which we call “rolling resistance.”

The understanding of the above explanation will go a long way towards understanding why wider tires have lower rolling resistance than narrower tires (for a given tire construction and pressure), why higher tire pressures (to a point) will reduce rolling resistance, why higher “thread count” tire casings (i.e. thinner materials) typically exhibit lower rolling resistance, why thinner tire treads will reduce resistance to rolling, why materials used to enhance puncture resistance can increase rolling resistance, and why certain inner tube materials are faster than others.

OK… so why are wider tires better rolling than narrower tires? How come all the “race” tires are so narrow if that’s the case?

One needs to be careful when making blanket statements like that. For a GIVEN TIRE CONSTRUCTION and INFLATION PRESSURE a wider tire will have a lower rolling resistance than a narrower tire. Why is this? This is merely because the area of the contact patch is driven by the load on the tire and the air pressure inside the tire. If these things are the same, a wider tire will naturally have a wider contact patch which, to keep the area the same, will require the length of the contact patch to be reduced. Since the overall length is reduced, this mean that the point where the “equivalent forces” we discussed above will be offset less from the axle, and therefore the torques caused by those forces will be reduced. Look again at Figure 2 to help understand this. Also, as we will discuss in the future, the materials used in a tire can have a dramatic effect on the tire properties. That’s why, the statement about wider tires rolling better than narrow tires needs the qualification of “for a given construction”. It’s very easy to make a wide tire that has higher rolling resistance than a narrower tire just by changing the tire construction.

Now, one thing that shouldn’t be forgotten is that for tires used in timed cycling events, there can be an aerodynamic penalty for using wider tires. Increasing the width of a tire also increases the total frontal area of the tire, thus increasing the aerodynamic drag. In addition, if the tire is dramatically wider than the rim to which it is attached, this can cause additional drag due to the air not flowing smoothly over the tire to rim transition. Now, if the tire is mounted on a low profile rim, this discontinuity won’t have a dramatic effect, but when we’re talking about deep section aero wheels, the effect could be significant. A good rule of thumb for aero wheels is to use a tire that is no wider than the brake track of the rim. The best thing to do is to contact the manufacturer of the rim in question and just ask them what width tire is best for their wheel. For an example, the engineers at Zipp have stated that their rims are “optimized” around a 21mm wide tire and a Hed H3 wheel is purportedly best with a 19mm wide tire.

So I want fast tires for my TTs and my Tri bike legs. Who wouldn’t? How do I go about figuring out what’s best for me? Don’t I need to worry about durability as well? How can I find this stuff out?

Those are some good questions. In reality, the best tire for a particular purpose is the fastest tire that also has the highest likelihood of allowing you to finish the event with a minimal chance of an equipment failure. The facts of the matter are that the things that make a tire “fast” (i.e. thin, flexible casings, thin tread, lack of puncture belts) are also the things that increase the chances of a puncture. Therefore, a person has to balance the speed gains against the potential time losses due to an equipment failure.

Luckily, over the last few years there have been a number of tests and evaluations published on the internet that can help a person select the tire that’s best for them. Here’s some links to a few of them:

http://www.rouesartisanales.com/article-1503651.html (there’s puncture resistance data too)

http://www.biketechreview.com/tires/AFM_tire_crr.htm

That’s probably enough for everyone to digest for now…in the next article in this series, I’ll talk a bit more about tire construction, how someone can evaluate tires effectively by themselves, and we’ll even delve into the controversial “clinchers vs. tubulars” debate.

(TOM ANHALT is a Mechanical Engineer and masters bicycle racer residing in Southern California with his patient wife and 2 young children. Shortchanged in life's genetic lottery (as regards sports physiology) he's cultivated an obsession with understanding and finding performance gains in his cycling equipment wherever it's practical.)