Giro Synthe questions answered

Our readers had many questions about the new Giro Synthe aero road helmet and Giro Sport Design R&D director Rob Wesson responded in detail. We had given the slowtwitch forum members the opportunity to post questions, and most of the technical details were covered. A variety of duplicated and sales / marketing questions were not posted to Rob Wesson and thus instead focused on the technical ones.

Slowtwitch: Is the life cycle of the helmet getting shorter and shorter, and thus the pressure to develop new products bigger and bigger?

Rob Wesson: The short answer is it depends. Some helmets can live in the line for many years; others may only last a few. Like any other consumer product these days, “New” is important but for Giro it’s all about the technology and value we can bring to a helmet category. Historically, Giro introduces a new high end road helmet every 3-4 years.

ST: When did you start with the development of the Synthe?

Rob: The idea of the Synthe helmet was briefed in late Summer/early Fall of 2012 – shortly after launching the Air Attack at the Tour de France.

ST: Which specific helmets was the Synthe tested against?

Rob: In no particular order: Mavic Plasma, Bontrager Oracle, POC Octal, Catlike Whisper, Lazer Genesis, Specialized Prevail & Evade, LG Course, Bell Gage & Star Pro, as well as our own Aeon & Air Attack.

ST: Is it possible for you to give yaw sweeps of the helmets you tested? Also did you test any of the better ventilated aero helmets such as the LG Course?

Rob: Transparency in aerodynamic testing is of the utmost importance for Giro. Multiple companies in the cycling industry market their product as “the fastest” or “most aerodynamic”, but they fail to provide their methodology or even what position/yaw angle this supports. And if they do list that yaw angle, does this actually clarify anything for the cyclist? Based on over 25 years of wind tunnel use; as well as compiling and analyzing massive amounts of data, we have decided as a Brand to only show Wind Average Drag (WAD) numbers. We know that not everyone has the opportunity, time or money to do their own wind tunnel testing. Therefore, we feel our testing methodology and the use of WAD most closely replicates the actual conditions riders experience in the real world. Additionally, we hope to inspire other companies in the cycling industry to adopt a similar testing methodology and the use of WAD. This would result in a more consistent and intuitive means of measuring and comparing aerodynamics.

ST: Can you explain in detail the yaw drag weighting, and how it was determined and applied?

Rob: Wind Average Drag in an analytic tool originally developed within the automotive industry during the energy crisis of the 1970’s by researcher, Ken Cooper. Cooper, who specialized in studying fuel economy, sought a means of simplifying research on automotive drag and its impact on fuel-efficiency. In a nutshell, WAD is a formula that aggregates the drag measurements from several discrete yaw angles into a single “wind Averaged” measure of drag.

Wind Averaged Drag was introduced to the sporting goods industry by aerodynamicist, Len Brownlie. Brownlie is an aerodynamicist with 20 years of experience with wind tunnel testing and a client list that has included Nike, the United States Olympic Cycling Team, the Canadian Olympic Committee, the United States and Dutch Speed Skating Teams, and countless high-profile professional athletes. Brownlie began working with Giro Cycling in 2004. It was in 2009, however, that Brownlie adopted WAD as a means of improving the testing and development of Giro’s Air Attack helmet.

Brownlie, like countless engineers before him, found (during wind tunnel testing) that every helmet had a “sweet spot”—a yaw angle at which it exhibited very little aerodynamic drag. This kind of data, however, provided Brownlie and the Giro researchers with no means of determining which helmet was actually the most

aerodynamic most of the time. Brownlie sought a simple and reliable metric that would answer this question and had been considering WAD for some time. In 2009, Brownlie contacted Cooper, who, along with researcher Dr. Peter Ostafichuk of the Department of Mechanical Engineering, University of British Columbia, helped adapt

WAD to the measurement of drag in cycling. The WAD calculation for cycling is essentially the same as the one used by Cooper for the study of fuel efficiency, with some small modifications to account for the size of a cyclist vs that of a semi-truck (Cooper’s primary area of focus).

As far as application: Same as our industry competitors, we test at 5 discrete yaw angles (0, 5, 10, 15, & 20 degrees) and at speeds of 25mph for road helmets and 30mph for TT helmets. The yaw angles and corresponding drag results are then input into our WAD calculator to compute the one WAD value.

For more information and indepth mathematical explanations, please see these following publications:

1. Cooper K., SAE Wind Tunnel Test Procedure for Trucks and Buses. SAE Recommended Practice J1252; 1979: August

2. Cooper K., Truck Aerodynamics Reborn—Lessons from the Past. SAE International Truck and Bus conference and exposition. SAE 2003-01-3376, Houston, TX; 2003 Nov.

3. Len Brownlie, Peter Ostafichuk, Erik Tews, Hilgard Muller, Eamon Briggs, Kevin Franks—The wind-averaged aerodynamic drag of competitive time trial cycling helmets. ISEA 2010.

ST: What about pitch data for the Synthe and the competitors it was evaluated against? With pitch we refer the angle that changes when you look further up or further down.

Rob: Our methodology includes two pitch angles. 30 degrees and 60 degrees; measured from the vertical plane. The 30 degree angle most closely represents a cyclist in their normal, steady-state position – fairly relaxed posture, hands either on the hoods or in the drops and looking forward. This 30 degree head angle also represents a TT rider in their tucked position looking up the road. The 60 degree position is when a rider dips or drops the head and looks down to rest the neck muscles. As with all testing, we are trying to simplify the static test parameters to most closely match real world conditions. Riding is dynamic and each consumer may have slightly different angles that their head is positioned at when riding. These angles were chosen based on multiple studies of athletes’ average riding positions.

ST: Given that the Synthe is supposedly more aero and cooler than both the Aeon and Air Attack, where does Giro see the market heading in the next 2-3 years?

Rob: Ah…Prognostications! At the high end, aero will still remain important for our competitive athletes and core cyclists. Great fit, ventilation, lightweight and aesthetics round out the priorities – this won’t change. New shapes and forms should always be expected as we learn more with each new helmet.

ST: Will we see all road helmets meld into this new generation of aero road helmets? If not, what will be the role of a high-end road helmet?

Rob: What we learned from the Air Attack and Synthe development will certainly carry over into other models if we feel it’s appropriate and correct for that market. By pushing our boundaries in these categories, we have created new shapes, new fit systems, new ways to manufacture that all may have relevance in other categories. A good example is our RocLoc 5 fit system. We launched this fit system on the Aeon 4 years ago at our highest price point. It then made its way into our $90 Savant model a few years later. And in 2015 you’ll be able to get it on an even lower price point helmet in our line.

ST: You now have 3 helmets targeting roughly one price point. Will we see helmets like the Synthe eventually sitting at the top of two converging lines – one side giving up aerodynamics for better ventilation and the other giving up ventilation for better aerodynamics as you go down the price line?

Rob: The Synthe is really the Synthesis of the best aerodynamics and the best ventilation in one helmet. Like my answer above, you will start to see the technologies introduced in these new high end helmets trickle down to lower price points to a certain extent. You are already seeing some of Giro’s new forms across our line that are inherently more aerodynamic and that will continue.

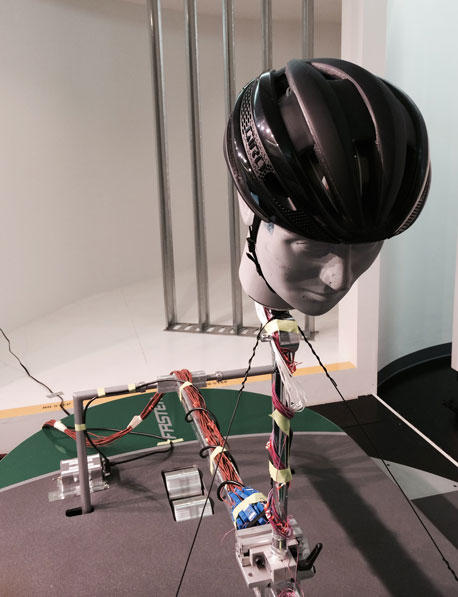

ST: Word has it that you used an instrumented aluminum head mannequin to help measure cooling rates. Did the head mannequin have a heater in it to simulate the roughly constant temperature of the interior of a human head? And how much do you think the test is affected by the significantly higher thermal conductivity of aluminum vs. a skull/skin?

Rob: Our Therminator heated head form is made from aluminum and does utilize internal heaters. With a constant power source, we are able to maintain roughly human head temperature throughout the helmet evaluation. While aluminum does have a higher thermal conductivity compared to skull/skin, it balances our need for a test fixture that is both efficient and consistent for capturing data. The human body utilizes very complex thermodynamic mechanisms to regulate heat – Conduction, Convection, Radiation and Perspiration. Our testing focuses primarily on convection.

ST: Have you run the your wind tunnel mannequin with a wig? Would you expect the hair to change how the air flows through the helmet? Would the bald head of the mannequin affect the difference you see between a helmet like the synthe, which has more air flowing over the head, and a helmet like the air attack, which has less flow. I would imagine repeatability would be difficult with the wig.

Rob: We have tried many different ideas and methods to understand air flow and heat transfer in helmet testing including wigs. As you pointed out, the repeatability is the largest issue. When testing, you are always trying to control and/or limit the number of variables so as to capture accurate and consistent data. This is why we (and all other competitors that I’m aware of) use a bare head mannequin. You are correct though that you will see a difference in both aerodynamics and thermodynamics when comparing a bare head form to one with a wig.

ST: Can you discuss the fundamentals of airflow around and through a helmet for aero vs non-aero helmets?

Rob: Aerodynamically, air wants to travel the path of least resistance. Therefore, the more you can reduce the frontal area and streamline a shape, the faster the air will flow around it. This is the fundamental rule for aero helmets. Anytime you add vents or other features that cause the airflow to change direction suddenly will generally increase the drag of the helmet. Similarly, when you want to optimize thermodynamics, what you are after is airflow. A helmet with a lot of vents all over doesn’t necessarily mean that helmet is well ventilated or cool. When adding vents to a helmet, air will only flow through a helmet if there is a clear path from an inlet to an outlet.

ST: Will there be a shielded version of the Synthe?

Rob: Currently there is no plan for shield for the Synthe

ST: Are we going to see this family of helmets start moving down the pricing spectrum towards the mid-range, where the average cyclist might actually be able to get them?

Rob: Technology has a way of trickling down the line in subsequent years and this is true here. Styling wise, we are launching the new Giro Foray this year at $65. This helmet will share a very similar profile to the Synthe but come with our standard RocLoc 5 fit system and no aero mesh panels.

ST: What international helmet safety standards will the Synthe meet? For example in Australia the Aeon and Air Attack are not legally allowed to be sold as they don't meet the AS/NZ standards years after release to market and there are concerns that Giro hasn't bothered to submit them for testing. Are there any plans for this helmet with the Aussie/NZ market or is that simply too small of a market?

Rob: The AS/NZ market does matter to us but there are a number of changes that have to happen to the helmets in order to meet the standards there. All of our helmets meet either the CE, CPSC or both standards. We are working on the AS/NZ standard now for many of our helmets including the Air Attack and Synthe but the release dates will be a little delayed. The Aeon has been available in Australia and New Zealand for over one year.

ST: Rob, can you comment more in depth on the Aero Mesh panels, and how they're being used to smooth out the airflow as opposed to traditional vents?

Rob: We found in our testing that the aero mesh panels do two things. First, the panels help streamline the helmet in this critical side area by covering up the edges of the side vents. Second, the mesh panel holes actually work dynamically to alter the boundary layer of air in this area; acting almost like an air bearing. As air enters the front of the helmet, the mesh panels slow down the movement of air from the inside to the outside of the helmet in this area. This air wants to escape but has to do so in a metered sense through the smaller mesh holes; instead of a quicker release through larger vents. This metered release changes the boundary layer in this area and thus improves the overall aerodynamics of the helmet.

ST: Why not cover the entire helmet in Aero Mesh, or is there a point at which the Aero Mesh is simply not channeling enough air and thereby causing drag?

Rob: Like any engineering challenge, you are trying to balance many different priorities. As stated in an above answer, aerodynamics, ventilation, weight and aesthetics all needed to meet their targets. The final version which you’ve seen pictures of is that balance.

ST: Also, is there a particular science to the shape of the holes in the Aero Mesh?

Rob: We found the size of the holes played a role in its effectiveness but we were set upon the general shape (circles fading to ovals) from an aesthetic view point and did not investigate multiple shapes.

ST: Where does this leave the technology of ear covers and tails?

Rob: Ear covers, tails and other typical TT helmet features are still valid for full on aerodynamic helmets, although their shapes and sizes are always evolving.

ST: Is the fit similar to an Air Attack?

Rob: Yes, the fit should be same as the Air Attack with RocLoc Air fit system.

ST: How do you keep the Bell team from copying what you are doing at Giro, or better said, how do you keep the identities separate?

Rob: Giro and Bell have different DNAs so to speak. We both have dedicated design, engineering, and marketing teams. Each brand also has its own management which sets the direction and projects that will be executed each year. While we may have helmets that compete in the same categories, the helmets will be decidedly different in aesthetics as well as features.